Submitting your good work to the knowledge base is easy. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http://www.allbest.ru/

Posted on http://www.allbest.ru/

Introduction

1. Microclimate and its impact on human health and performance

2. Microclimate of workplaces

3. Means for measuring microclimate indicators

3.1 Air temperature

3.2 Airflow speed

3.3 Relative humidity

4. Hygienic standardization industrial microclimate

5. Means of protection against industrial microclimate

Conclusion

List of used literature

INTRODUCTION

Microclimate- these are meteorological conditions that are determined by the set of physical parameters of the air environment acting on the human body in small open or closed spaces (up to tens and hundreds of meters in diameter). Indicators characterizing the microclimate of industrial premises are: temperature, humidity, air speed and thermal radiation.

In this test we will consider the impact on the human body, microclimate regulation, protective equipment and many other facts. The purpose of this test work is to get acquainted with the purpose of maintaining health, creating a comfortable state of the living environment that complies with regulatory parameters in workplaces of the production environment, in a person’s everyday life and recreation areas.

1. MICROCLIMATE AND ITS INFLUENCE ON HUMAN HEALTH AND PERFORMANCE

The microclimate of industrial premises is the climate of the internal environment of these premises, which is determined by the combinations of temperature, humidity, and air speed acting on the human body. Microclimate influences the heat transfer process and the nature of work. Long-term exposure to unfavorable conditions sharply worsens a person’s well-being, reduces labor productivity, and leads to illness.

1) exposure to high temperatures quickly tires and can lead to overheating of the body, heatstroke or occupational diseases. industrial microclimate hygienic humidity

2) low temperature - local or general cooling of the body, the cause of colds or frostbite.

3) high relative humidity at high temperature promotes overheating of the body; at low temperatures, it increases heat transfer from the surface of the skin, which leads to hypothermia.

4) low humidity causes drying of the mucous membranes of the respiratory tract.

2. WORKPLACE MICROClimate

During any work and even at rest (during sleep), a person expends energy, the equivalent of which is released from the body in the form of heat. The environment must absorb heat adequately. If the microclimate does not correspond to the work being performed, the body may overheat or become hypothermic.

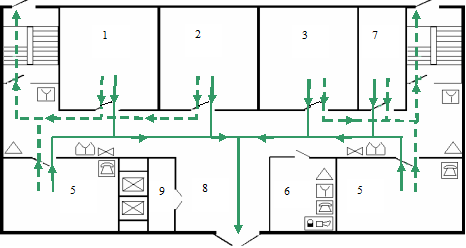

The most effective way of heat transfer is radiation Q glad. Next comes heat transfer by contact Q pressure and moisture evaporation Q Spanish For convective heat transfer and heat loss through respiration q accounts for no more than 5% (Fig. 15.1).

If allocated and allotted are equal Q into the environment of heat we can talk about comfort meteorological conditions:

Q = Q glad + Q knd + Q and sp + q.

The efficiency of the channels in the total amount of heat involved in the exchange process is distributed as follows:

Rice. 15.1 Efficiency of heat exchange channels

The standardized components of the microclimate are influenced by the category of work, determined on the basis of the total energy expenditure of the body in kcal/h (W). Based on this indicator, work is divided into several categories.

CategoryIA. Work with an energy intensity of up to 120 kcal/h (up to 139 W), carried out while sitting and accompanied by minor physical stress (a number of professions in precision instrumentation and mechanical engineering enterprises, watchmaking, clothing production, management, etc.).

CategoryIb. Work with an energy intensity of 121-150 kcal/h (140-174 W), performed while sitting, standing or associated with walking and accompanied by some physical stress (a number of professions in the printing industry, at communications enterprises, controllers, craftsmen in various types production, etc.).

CategoryIIA. Work with an energy intensity of 151-200 kcal/h (175 - 232 W), associated with constant walking, moving small (up to 1 kg) products or objects in a standing or sitting position and requiring a certain physical stress (a number of professions in mechanical assembly shops of machine-building enterprises , in spinning and weaving, etc.).

CategoryIIb. Work with an energy intensity of 201 - 250 kcal/h (233 -290 W), associated with walking, moving and carrying weights up to 10 kg and accompanied by moderate physical stress (a number of professions in mechanized foundries, rolling, forging, thermal, welding shops, machine-building and metallurgical enterprises, etc.).

CategoryIII. Work with energy consumption of more than 250 kcal/h (more than 290 W), associated with constant movement, moving significant (over 10 kg) weights and requiring great physical effort (a number of professions in forge shops with manual forging, foundries with manual filling and pouring of flasks etc.).

The efficiency of heat exchange channels is determined by the following standardized microclimate indicators:

Air temperature, °C;

Temperature of enclosing surfaces, °C;

Air speed, m/s;

Relative air humidity, %;

intensity of thermal radiation, W/m 2.

3. TOOLS FOR MEASURING MICROCLIMATE INDICATORS

3.1 Air temperature

Posted on http://www.allbest.ru/

Posted on http://www.allbest.ru/

It is measured with any thermometer, with an error of no more than ±0.2 °C. For this purpose, it is better to use a stick thermometer, the divisions of which are located directly on the body of the device. This eliminates unauthorized movement of the scale relative to the capillary, reducing measurement error. Currently, electronic devices are widely used, for example, the domestic TAM-1 hot-wire anemometer with a measurement range from 0.1 to 2.0 m/s, temperature and humidity meters TKA-TV or testo 415 manufactured in Germany (Fig. 1). All devices are powered by batteries that provide a service life sufficient for certification. At the same time, the thermohygrometer testo The 415 measures both RMS and maximum values.

3 .2 Air speedcurrent

The air flow speed is determined in various ways. The action of the simplest device - a catathermometer based on the intensity of heat exchange with the environment, which is why it is also called a thermal anemometer. The advantage of the device is that it covers the entire range of standardized air flow rates. With its help, you can determine the air speed in the range of 0.02 - 0.5 m/s.

Among mechanical instruments, the ASO-3 type vane anemometer (measurement range 0.3-5.0 m/s) has limited use due to its high lower measurement limit. It is equipped with a multi-scale dial consisting of a main scale and two auxiliary ones.

3 . 3 Relative humidity

Relative humidity is the ratio absolute humidity(numerator) to maximum (denominator), expressed as a percentage, characterizes the moisture content in the air volume:

where are the values E And E" - moisture content at dry readings t dry and wet t vlzh thermometers are taken according to psychrometric tables.

Values t dry And t vlzh obtained using an aspiration psychrometer.

It is convenient to measure relative humidity with digital instruments, for example, a domestically produced IVA-6 thermohygrometer.

Besides relative humidity it measures the air temperature. The thermohygrometer fully meets the requirements for certification of workplaces for working conditions.

In workplaces with a heating microclimate (maintenance of boiler installations and heating stations, welding and forging work, clothing washing stations, etc.) regardless of the period of the year and in open areas during the warm period of the year (construction, repair, track and similar work), The indicator characterizing the microclimate is the intensity of thermal radiation. Its value is characterized by the index thermal nAenvironmental loads TNS.

This empirical integral indicator characterizes the combined effect of microclimate parameters (temperature, humidity, air speed and thermal radiation) on the human body and evaluates it with a single-digit indicator in degrees. It was first established by the international standard ISO 7243-1982 “Elevated temperature environments - assessment of the influence of heat load on a working person, based on the wet-bulb and bulb-bulb temperature index” and is designated as W.B.G. - index.

The index of thermal load of the environment is recommended to be used for an integral assessment of the thermal load of the environment in workplaces where air movement speed does not exceed 0.6 m/s and the intensity of thermal radiation is 1200 W/m 2. The THC index values should not go beyond the recommended values (Table 1)

Table 1. The magnitude of the thermal load of the environment to prevent overheating of the body

A radiometer can be used to measure the intensity of thermal radiation (W/m2) Argus-03 domestic production. This is a compact, battery-powered device with a receiver viewing angle of at least 160 o.

Automated systems for measuring THC index ( WBGT- index by international standard ISO 7243) can be either single or multi-channel. They allow you to perform the necessary measurements in parallel at three points and display the result on the built-in display and/or printer.

To measure the intensity of thermal radiation, radiometers with a receiver viewing angle of at least 160° and sensitivity in the infrared and visible regions of the spectrum are used. One of them is a radiometer type Argus-03. Actinometer-type devices can also be used.

Microclimate indicators are measured at outside air temperatures that differ from the average winter or summer values by no more than 5°C.

In order to protect personnel from overheating or hypothermia, the total time

stay at the workplace during a shift should be limited - time protection. Shift average air temperature is calculated using the formula:

Where t i and t i - temperature (° C) and duration of stay (min) of the worker at i- that area of the workplace.

When choosing areas and measurement times, it is necessary to take into account all factors affecting the microclimate of workplaces (phases of the technological process, functioning of ventilation and heating systems, etc.). Microclimate indicators are measured at least 3 times per shift (at the beginning, middle and end). In case of their fluctuations associated with technological and other reasons, additional measurements are carried out at the highest and lowest thermal loads on workers. If workplace- several sections of the production facility, measurements are carried out at each of them.

In rooms with a high density of workplaces in the absence of sources of local heat generation, cooling or moisture release, areas for measuring microclimate parameters should be distributed evenly over the area: up to 100 m 2 - 4 areas; 100 - 400m 2 - 8 plots; over 400m2 - the number of sections is determined by the distance between them, which should not exceed 10m.

4. HYGIENIC STANDARDING OF PRODUCTION MICROCLIMATE

Norms of parameters of meteorological conditions in production premises regulated by GOST 12.1.005-88 “General sanitary and hygienic requirements for the air of the working area.” The standard establishes requirements for air temperature, relative humidity, and air speed for the working area of industrial premises in the form of optimal and permissible values, taking into account the period of the year and the severity of work activity.

Standards for the parameters of meteorological conditions are established for the working area - a space up to 2 meters high above the floor or platform on which the place of permanent or temporary residence of a worker is located. A permanent place is considered to be where the worker spends more than 50% of his working time or more than 2 hours continuously.

Standardized microclimate parameters in industrial premises SanPiN 2.2.4.546-96 by season: cold or warm. Cold season characterized by an average daily outside air temperature of +10°C and below, and warm - above +10°С.

Average daily outside air temperature - the average value of outdoor air temperature measured at certain hours of the day at regular intervals. It is taken according to the meteorological service. In accordance with the specified sanitary standards and rules, the microclimate parameters of production premises can be optimal and acceptable.

Optimal microclimatic conditions established according to the criteria of optimal thermal and functional state person. They provide a general and local feeling of thermal comfort during an 8-hour work shift with minimal stress on the thermoregulation mechanisms, do not cause deviations in health, and create the prerequisites for a high level of performance, therefore they are preferred in the workplace.

The list of other workplaces and types of work in which optimal microclimate values must be ensured is determined by the Sanitary Rules for individual industries and other documents agreed upon with the State Sanitary and Epidemiological Supervision authorities in the prescribed manner.

Optimal microclimate indicators at work Those that correspond to the recommended values (Table 2) are recognized as applicable to work of various categories in the cold and warm periods of the year. Changes in air temperature in height and horizontally, as well as changes in air temperature during a shift should not exceed 2°C and not go beyond the specified limits.

Optimal microclimate indicators must be observed at workplaces of industrial premises where operator-type work associated with neuro-emotional stress is performed (in cabins, at consoles and control stations for technological processes, in computer rooms, etc.).

Table 2. Optimalindicatorsmicroclimate in industrial workplaceselow temperatures (at relative humidity 40-60%)

Acceptable microclimatic conditions established according to the criteria for the permissible thermal and functional state of a person for the period of an 8-hour work shift. They do not cause damage or health problems, but can lead to general and local sensations of thermal discomfort, tension in the thermoregulatory mechanisms, deterioration of well-being and decreased performance.

Acceptable microclimate indicators are established in cases where, due to technological requirements, technical and economically justified reasons, optimal values cannot be ensured. In this case, the difference in air temperature in height should be no more than 3°C, and horizontally and during a shift should not exceed 4°C for work category I; for categories II - 5°C; in categories III - 6°C.

During the warm period of the year, when the air temperature in the workplace is 26-28°C, its speed must correspond to the recommended range, and the relative humidity at an air temperature of 25°C and above should not exceed the established limits.

If at least one of the parameters does not correspond to the given values, the working conditions at the workplace are considered unsatisfactory, and the workplace itself is characterized as “conditionally certified”. This means that the parameters of the determining factor must be brought to acceptable values.

To measure microclimate indicators, you should choose devices that provide error in the results.

In workplaces with a heating microclimate (maintenance of boiler installations and heating stations, welding and forging work, clothing washing stations, etc.) regardless of the period of the year and in open areas during the warm period of the year (construction, repair, track and similar work), The microclimate indicator is the intensity of thermal radiation. The empirical integral indicator of THC reflects the combined impact of all microclimate factors, including thermal radiation.

5 . PROTECTION MEANS AGAINST INDUSTRIAL MICROCLIMATE

In production conditions, there are situations when, due to the requirements of the technological process or technical unattainability and economic inexpediency, it turns out to be impossible to ensure acceptable standard values for the parameters of meteorological conditions; in such cases, special measures are provided to protect workers from possible overheating or cooling.

Basic preventive measures in production:

Mechanization and automation of heavy and labor-intensive work, the implementation of which is accompanied by excessive heat generation in the human body;

Remote control of heat-emitting processes and devices, which eliminates the need for workers to stay in the infrared radiation zone;

Construction of protective screens, air and water curtains that protect workplaces from thermal radiation;

Rational placement and thermal insulation of equipment, apparatus, communications and other sources that radiate heat to workplaces;

Installation of thermal curtains at the entrance to the workshop to prevent the entry of outside cold air into the premises;

Covering sources of intense moisture release with casings, covers or installing local suction;

Installation of aeration or mechanical ventilation in the presence of powerful sources of heat and moisture in production premises;

Arranging rooms for short-term rest in hot shops, supplying them with purified and cooled air;

Construction of specially equipped rooms for periodic heating of workers working for a long time in the cold.

CONCLUSION

At the end of the test, we can conclude about the microclimate that a certain combination of temperature, relative humidity and air speed is important for a person’s thermal well-being.

Microclimate also determines the need to develop physiologically based parameters of temperature, humidity and air speed, which would take into account the specifics of various industries, the variety of technological processes, and labor intensity. Such studies to assess the influence of a set of parameters of meteorological conditions on human heat exchange were carried out by occupational hygiene institutes. Based on this, GOST 12.1.005-88 “General sanitary and hygienic requirements for the air of the working area” was created. The main content of preventive supervision is monitoring compliance with sanitary standards and rules during the design and construction of industrial facilities. The task of current sanitary supervision is to monitor compliance with sanitary legislation at operating enterprises. One of the elements of current sanitary supervision is the study of working conditions at industrial enterprises in order to prevent occupational and general morbidity. The regulation of the industrial microclimate is regulated by the same GOST.

To measure air temperature, GOST 12.1.005-88 recommends using aspiration psychrometers to measure temperature, especially since the study of weather conditions involves the simultaneous determination of air humidity, and for measuring relative air humidity, an ASSMANA aspiration psychrometer type M-34.

Anemometers of various designs are used to measure air speed. The choice of anemometer type is determined depending on the purpose of the study and the magnitude of the measured air velocity.

The ASO-3 vane anemometer allows you to measure air speed in the range from 1 to 10 m/s.

Cup anemometer is designed to measure average speed air flow from I to 20 m/s.

A ball catathermometer is used to measure low air velocities.

The main thing is to use technical means to prevent or reduce exposure of workers to harmful or hazardous production factors, as well as to protect against pollution.

LIST OF REFERENCES USED

1. Kuznetsov K.B., Vasin V.K., Kupaev V.I., Chernov E.D. Life safety. Part 1. Life safety in railway transport: Textbook / Ed. K.B Kuznetsova. M.: Route, 2005 - 576 p.

2. Kuznetsov K.B., Vasin V.K., Bekasov V.I., Mezentsev A.P., Chepulsky Yu.P. Life safety. Part 2. Occupational safety and health in railway transport: Textbook / Ed. K.B Kuznetsova. M.: Route, 2006 - 536 p.

3. Troshunin V.V. Zvigintseva G.V. Ivashova Z.I. Study of microclimate indicators in the working area of production premises: Laboratory work. Ekaterinburg, 2004 - 21 p.

Posted on Allbest.ru

...Similar documents

Microclimate parameters in the workplace: humidity, temperature, air speed, thermal radiation. Determination of optimal microclimatic conditions. Instruments for studying microclimate parameters: thermometers, psychrometers, hygrometers.

test, added 10/30/2011

Four factors for assessing microclimate: temperature and air speed, relative humidity and thermal radiation. Formula for determining the comfort of meteorological conditions. Means for measuring microclimate indicators of an industrial enterprise.

presentation, added 03/17/2014

The importance of microclimate in the workplace for human health. Adverse effects of industrial microclimate, methods for reducing its impact. Carrying out sanitary, technical, organizational and medical preventive measures.

presentation, added 05/21/2013

Microclimate of industrial premises. Temperature, humidity, pressure, air speed, thermal radiation. Optimal values of temperature, relative humidity and air speed in the working area of production premises.

abstract, added 03/17/2009

Microclimate parameters and their measurement. Thermoregulation of the human body. The influence of microclimate parameters on human well-being. Hygienic standardization of microclimate parameters. Ensuring normal meteorological conditions in the premises.

test, added 06/23/2013

Microclimatic conditions of the production environment. The influence of microclimate indicators on the functional state of various body systems, well-being, performance and health. Optimal and acceptable microclimate conditions in the working area of the premises.

abstract, added 10/06/2015

The influence of microclimate parameters on human well-being. Hygienic standardization of microclimate parameters. Means for ensuring proper cleanliness and acceptable microclimate parameters of the working area. Requirements for lighting of premises and workplaces.

presentation, added 06/24/2015

Description of the microclimate of industrial premises, standardization of its parameters. Instruments and principles for measuring temperature, relative humidity and air speed, intensity of thermal radiation. Establishment optimal conditions microclimate.

presentation, added 09/13/2015

Study of temperature, humidity and air speed in the production premises of Abakan-KAMI LLC. Comparison of actual values of microclimate parameters at the enterprise with standard values. Analysis of their impact on staff performance.

course work, added 07/13/2011

Microclimate as a factor in creating favorable working conditions. Optimal and permissible values of microclimate indicators. Thermoregulation of the human body. Features of normalization of microclimate indicators. Basic measures to ensure microclimate standards.

Heat, poor lighting and noise not only cause discomfort, but also affect safety, health and work efficiency. Although we feel, see and hear all these conditions, we often try not to notice them.”

Working conditions affect labor productivity

Temperature environment, quantity and quality of lighting and noise levels are common factors in the working conditions of any workplace. These conditions can affect the safety and health of workers in factory settings where mechanization and automation have brought changes. These factors, if excessive or inappropriate, can greatly affect the completion of a production task and its efficiency.

All this affects danger and health. For example, heat and humidity cause increased fatigue in the worker and increase potential health risks; in addition, when there is noise, warning signals cannot be heard or may be misunderstood, and, ultimately, noise leads to permanent hearing loss.

Technologies to regulate temperature, provide adequate lighting and reduce noise are constantly evolving, creating efficient production flows to protect workers from health hazards. We must identify existing operating conditions and try to change them by finding practical solutions.

In this chapter we will discuss:

working area climate

thermal stress

· methods of protection

· consequences

· lighting

exposure to noise

methods of noise control

· Hearing protection.

Working area climate

Climate can be defined as the atmospheric conditions that surround us. It could be general conditions in a geographical area or, in a narrower sense, the local atmospheric conditions at a specific workplace. Often the climate of the working area (also called microclimate) is determined by the general climate.

During the hot season, people feel uncomfortable and productivity drops. By applying new technology and living standards, it is sometimes possible to achieve some degree of climate control in the places where we live and work. However, in the workplace or outdoors we are often exposed to unbearable heat and therefore measures should be taken to protect ourselves from harmful exposures.

It is possible to alleviate the effects of heat with air conditioning, but this is expensive and not universally applicable. It is also important to ensure sufficient accumulation of fresh air.

Body heat exchange

As a result of physical work, our body releases heat. To maintain normal body temperature, the body must get rid of excess heat. The body's heat exchange must be maintained.

Heat transfer refers to the usual balance between heat received and heat given off.

There are three main sources of heat:

air temperature, air speed and humidity

Radiation from the sun, machines and processes

· muscular work.

In addition, there are three ways to release heat:

· convection (transfer of heat from the body to the environment), the stronger the wind, the higher the heat loss. Conversely, we absorb heat when the ambient temperature is higher than body temperature,

· radiation (when the body gives off heat to cooler surrounding objects). But if the body is located close to heated surfaces, then it absorbs heat. This happens when a person is in the sun, near a stove, heated container, etc.

· evaporation (when sweating, water evaporates from the surface of the skin and removes excess heat). Naturally, this type of heat loss through evaporation is easier when there is wind and becomes more difficult when there is high humidity.

Thus, in hot climates, the body can absorb heat in different ways, but the only way to effectively get rid of excess heat is through evaporation.

In order for the body to cope with the task of heat balance, these factors must not exceed certain limits. The range may vary from person to person and may vary depending on the time of year, clothing, severity, work performed and culture. However, all people accept a comfort zone of approximately 20 to 25 degrees Celsius with a relative humidity of 30% to 70%, if physical activity is light and there is no heat source nearby.

As physical activity increases, cooler air temperatures are required to maintain a comfortable state. Since when performing heavy physical work the body generates heat with its muscular energy, a feeling of comfort is achieved at temperatures below 20 degrees Celsius.

An increase in wind speed can serve as a comfort factor if the ambient temperature is at or above the upper limit of the comfort zone. Movement speed 0.1-0.3 m/sec. favorable for creating a comfort zone when performing work associated with light physical labor.

When the local climate does not allow the body to get rid of excess heat and reach a normal temperature, a person experiences real discomfort. As a result, performance drops sharply. In extreme cases, you can reach complete exhaustion and loss of health.

Remember!

· The body has the ability to reach its normal temperature by getting rid of excess heat. Outside the comfort zone, this ability to regulate heat balance is lost. The discomfort you feel in a hot zone is an important warning sign.

Thermal stress measurement

The degree of thermal stress can be measured by measuring the hot zone, or by measuring the condition of the body exposed to that zone.

Measuring working conditions

There are four main parameters that influence the degree of thermal stress:

air temperature

relative humidity

temperature measured by a spherical thermometer (radiation temperature)

· air speed.

To measure these parameters, the following instruments are required:

· Thermometer (glass thermometer) is used to measure air temperature in the shade. The air temperature can vary from minus to approximately +50 degrees Celsius.

· Wet bulb thermometer is used to determine humidity using a glass thermometer. The lower part or bulb of the thermometer is wrapped in gauze; the end of the gauze (not the bulb itself) is placed in a jar of water. If the air is dry, the water from the gauze will evaporate quickly and the temperature will drop. If the humidity is high, the water will evaporate slowly and the dry-bulb and wet-bulb temperatures will differ slightly. Using the difference between two temperature indicators in the table, you can determine the percentage value of relative humidity. Relative humidity ranges from 0% to 100%.

· A spherical thermometer is used to measure radiation temperature, which can differ significantly from air temperature. The thermometer bulb is placed in the middle of a hollow black copper sphere with a diameter of 15 cm. The black sphere absorbs radiation and warms the air inside it.

· An anemometer detects wind speed. An alternative option is to use a Kata thermometer, which only has two marks. It is placed in warm water and kept there until the mercury rises to the upper level. Then it is wiped dry and placed in the air. A stopwatch measures the time it takes for the mercury to fall from the top to the bottom. Using the accompanying table, you can determine the wind speed based on the time required to cool the thermometer.

|

|

AIR TEMPERATURE is measured using a conventional thermometer. The thermometer tip is protected from direct radiation by a polished cylinder with holes at both ends. The readings are taken in approximately 5 minutes. AIR HUMIDITY can be measured using dry and wet hydrometers. Other instruments can be used, such as a thermohydrograph, which records humidity over a longer period of time. RADIATION TEMPERATURE is measured using a spherical thermometer. The readings are taken after 20-30 minutes. AIR SPEED can also be measured with a device specially designed for very low air speeds (0.2 m/sec), which is often observed in work areas. |

In some cases, all four of these measurements can be combined into a single unified thermal stress rating.

It is important to ensure that the air temperature does not deviate significantly from the comfort zone temperature and that the radiation temperature is lowest in areas where work is carried out, especially when relative humidity is high. It should be noted that a slight breeze helps to get rid of the discomfort.

Measurements of the human body

If a worker is in a state of thermal stress, the body temperature rises. The body responds to this through various defense mechanisms to ensure that the body temperature remains constant. The temperature of the skin rises (the heartbeat quickens, breathing becomes deeper), and the person begins to sweat. Thus, body temperature (measured by placing a thermometer in the mouth) indicates all the protective changes occurring in the body. However, body temperature should not change by more than 1 degree Celsius.

Based on studies of heat stress in industry, it was found that the level of sweating can serve as an indicator of body stress. The amount of sweat produced during working hours is measured by calculating weight loss, taking into account the weight of food and drink consumed, fumes and any changes in clothing. In a hot shop, weight loss after a work shift can amount to several kilograms.

Sweat contains salt. When you sweat profusely, the body loses a large amount of salt. In extreme cases, muscle spasms occur due to lack of salt.

Loss of water and salt during sweating must be restored. Unfortunately, when you feel thirsty, drinking water is not always enough. A healthy young man in a very hot workshop can lose up to 1 liter of sweat per hour. But it can usually withstand a loss of up to 4 liters over an 8-hour work shift, provided it replaces the loss of water and salt. To do this, you need to drink clean water or fruit juices. It is beneficial to add salt to your food and eat foods that contain natural salt or other minerals.

If, when sweating, you do not replenish the losses by drinking, then the body secretes very little urine, and the urine itself is thick and dark in color, and this is very harmful to health.

Sweating is necessary. The body does not sweat unnecessarily. It is dangerous to reduce sweating by reducing water intake.

There are two medical consequences of heat disturbance: heat exhaustion and heat stroke.

· Heat exhaustion occurs when a person feels dizzy and faint because there is not enough blood flowing to the brain. Blood pressure drops. You need to lie down in a cool place so that blood flows to your head.

· Heatstroke occurs when a person's skin is very hot and dry, caused by abnormal sweating mechanisms. There is a rapid increase in body temperature up to 40 degrees Celsius, which is often accompanied by a decrease in sweating. In this case, you must urgently call a doctor or provide medical assistance. While waiting for help, it is vital to cool the body with wet sponges.

Remember!

· Sweating is necessary. The body does not secrete sweat unnecessarily, since the loss of water and salt through sweating is not indifferent to health, one must try to create working conditions in which workers do not sweat a lot. It is dangerous to reduce sweating by reducing the amount of fluid you drink.

Acclimatization occurs when a person lives and works in a hot climate. This means that the person has adapted and become accustomed to the hot climate. In fully acclimatized workers, heart rate and body temperature react less when working in a hot environment. They may have blood circulation closer to the surface of the skin.

However, there are limits to the body's adaptability. Even for a fully acclimatized person, thermal stress should be kept to a minimum.

Questions:

· Is the local climate in a good zone?

· What are the signs that indicate that a worker is suffering from severe heat pressure?

· What factors increase thermal pressure?

· How does the body protect itself from heat?

· Is cool drinking water provided at your workplace?

Thermal protection

How to make your workspace cooler

There are several ways to cool the atmosphere in the workplace. Main idea is to protect the workplace from the penetration of external heat and increase ventilation, this is traditionally done in dwellings located in tropical climates. Don't forget:

· keep the evening cool as long as possible by ventilating the room in the evening, taking into account the layout of the building. In places far from the sea, it is usually much cooler in the evenings and in the morning than in the daytime

· open windows and doors wider to increase natural ventilation,

avoid floor coverings that retain heat, such as soil, wood, carpets, try to increase air circulation under the floor,

· The roof structure must be such that heat can escape outside. Particularly important is the material from which the roof is made and the design of the roof itself. Good ventilation under the roof significantly reduces indoor heat. To avoid direct radiation coming from the roof, the roof or ceiling material must be replaced. A roof painted in light colors will reflect the heat coming from the sun and sky,

· extend eaves or other overhangs so that the walls are in the shade for as long as possible. The walls, especially those on the sunny side, should be painted in light colors. For wall materials, do not use metal or other thin surfaces that are easily heated by the sun.

· When painting indoor walls, use a light range of colors. Light-colored surfaces emit less heat than dark ones. Light colors also psychologically create a feeling of coolness.

· ceilings must be high. High ceilings are better than low ceilings, install ventilation devices. Artificial ventilation helps to improve air flow: removing heated air and introducing cool air.

· Use electric fans to circulate air.

Machines and manufacturing processes that generate heat

Thermal stress increases significantly when using equipment and manufacturing processes that generate heat. The operator must be protected from heat.

This can be done subject to the following rules:

· Heat-generating equipment and processes must be located outside or in contact with the outside of the building so that heat can be released to the atmosphere.

· Hot surfaces must be insulated by applying materials such as foam or polyester to the metal surface. This preserves heat, saves fuel consumption and reduces the possibility of accidents associated with contact of a hot surface and the body,

· barriers are installed between the hot zone and the workplace. Effective heat-protective barriers can be shields with a reflective surface made of aluminum, water curtains, screens made of panels covered with wood or fabric,

· Heat aprons and other clothing, such as aluminum-coated vests, help protect against heat. However, this approach is not suitable for work involving prolonged heavy workload, because the high degree of insulation of clothing prevents the removal of heat through evaporation.

It is rarely possible to reduce strong radiated heat using an exhaust fan. The only one in an efficient way A partition may separate the hot zone and the workplace so that hot air flows are not directed at workers.

Remember!

It is no coincidence that some traditional dwellings in shady forests they are attracted by their coolness. They use different ways eliminating unnecessary heat radiation and increasing ventilation. We should act as wisely as our ancestors did. Make the best use of vents, partitions, screens and natural ventilation.

Air conditioning

Air conditioning allows you to adapt the indoor climate to the comfort and health of people. Typically, an air conditioning system simultaneously controls temperature, humidity, and air purity. Air conditioning is a very expensive piece of equipment, especially in factories, but can sometimes be a worthwhile investment. It is common knowledge that air conditioning increases productivity, helps reduce accidents, reduces absence from work due to illness and improves human relationships.

The air conditioning system must:

be of such a type as to satisfy the requirements of the premises,

· take into account the concentration of gases, vapors and dust in a given room,

· adjust the functions of the system in accordance with the comfort of people working in the room, and not depending on the readings of the thermometer,

· avoid hypothermia and drafts,

· Ensure that air conditioning equipment, including its humidity control elements, is well maintained.

What you need to do to prevent your body from overheating

Besides these technical measures you need to know how to prevent overheating. Thermal energy comes from inside the body. There are several ways to reduce heat generation and make it easier to release. Try:

avoid unnecessary rapid movements,

· think about how to do physical work with the least amount of effort, trying to stay less in the hot zone,

Avoid direct sunlight

· sit or stand in places where a gentle breeze blows from open doors, windows or from fans,

· Avoid closed spaces where air circulation is limited. If you work while sitting, use a seat that allows air to pass through.

·Keep away from heat sources such as hot liquids, equipment and fire. Where possible, install partitions,

· do not wear tight clothing or clothing that interferes with evaporation through sweating,

Drink soft drinks regularly

· Choose cool places to relax.

When working in a hot zone, it is very important to improve the working conditions and living conditions of workers. Exposure to heat combined with physical activity tends to be cumulative. It is extremely important to organize your working time correctly. Don't forget:

avoid long periods of work in hot areas where working conditions are particularly stressful,

· take breaks from work, especially when performing moderate to heavy physical work performed in hot, humid or radiant climates, 50% of work time or more is recommended for rest to prevent body temperature from rising. Shorter run time does not necessarily mean less productivity,

Organize a cool place to rest,

· provide sufficient cool drinking water near the workplace. Liquids should be drunk in small quantities, but often,

· provide the opportunity to shower or clean work clothes.

Remember!

· The heat generated by the body during physical work is added to the heat coming from the environment. Many people doing heavy physical work in front of stoves or other hot areas have a body temperature that reaches 39°C. In order to cope with a high temperature, you need to reduce physical activity and rest more often.

Questions:

· What are the main technical measures against heat?

Cold protection

People who work in cool indoor or outdoor environments during the winter, as well as people who handle refrigerated or frozen food, are exposed to the cold. Large temperature difference between the cool room and external environment is inconvenient and can be harmful to health. Exposure to the cold for a short period of time can also have serious consequences, especially if the temperature drops below 10°C. Heat loss from the body occurs due to unpleasant sensations and quickly affects labor productivity. Exposure to the cold for long periods of time or very cold external conditions can be life-threatening due to a sharp drop in body temperature.

Exposure to cold can be reduced by wearing thick, warm clothing and gloves.

In cold climates, heat loss from the body is enhanced by air movement. Indeed, the most better protection cold can cause a decrease in air flow over the surface of the body, thus reducing heat transfer through convection and evaporation. This can be done both with clothing and protection from the wind.

Working in a cold area causes some problems, such as:

· First the palms and soles freeze, then the arms, legs and finally the whole body.

· Workers experience a loss of coordination of movements, which reduces the speed and quality of work, as well as labor safety. In addition to the feeling of awkwardness, the ability to concentrate decreases. The discomfort caused by the condition affects safety.

· Bulk clothing is dangerous. It makes movement difficult; in addition, parts of clothing can get caught in working parts of machines. The same applies to thick gloves.

· When working with metals and liquids, your hands cool down faster.

· Exposure to cold, especially at temperatures below 0°C, can cause frostbite on the fingers and toes, nose, and ears. It is disturbing as well as painful and dangerous.

· Wet cold is more unpleasant than dry cold. This is mainly because humidity reduces the insulating properties of all types of clothing except wool.

Remember!

· Cold has a significant impact on safety, even if the worker is exposed to cold for a short period of time.

|

|

HIGH TEMPERATURE OPERATION Use thick gloves with a rough surface, such as leather. The inner gloves (or lining) should be made of heat-resistant material. Some glove designs can withstand temperatures up to 400°C. WORKING IN HUMIDITY AND COLD Use short gloves with a knitted lining and a waterproof top. LEATHER GLOVES Used to perform work involving moving heavy objects in a dry environment. If the most vulnerable parts of the gloves are reinforced with an additional layer of material, they will last longer. WORKING WITH CHEMICALS Use long chloroprene rubber gloves with moisture-absorbing fiber knit lining and long cuffs. |

Heating is not as expensive as air conditioning, and well-designed clothing can provide protection from almost any climate. However, it is necessary to think carefully and take into account the following conditions:

· When choosing clothing, you need to take into account protection from moisture and wind. The body sweats at any temperature.

· Waterproof clothing prevents evaporation. In this case, it becomes damp from the inside. Appropriate clothing provides both moisture evaporation and protection from rain and wind.

· Bulk clothing should be avoided as it impedes movement.

· When performing heavy work, overheating while wearing warm clothing may present serious problem. You should wear layers of clothing (vest, shirt, pullover, windbreaker) so that you can gradually undress, or wear quilted clothing with zippers.

· Hands and feet are especially sensitive to the effects of cold.

· Older people should be better protected from the cold than younger people.

· Equipment and production tasks should be designed to be less hazardous and easily accomplished (e.g., size and spacing of triggers, insulation metal parts, elimination of sharp protrusions, etc.).

· It is very important to provide comfortable heated places to rest.

Questions:

· Are there situations in your workplace where workers are exposed to the cold? Are workers aware of the dangers associated with cold?

· What specific safety precautions need to be taken when working in the cold?

Lighting

The color of the iris determines the color of the eyes. The black hole in the middle of the iris is the pupil. The size of the pupil is determined by the intensity of the light flux falling on it.

EYES NEED SUFFICIENT LIGHTING.

We often forget how important lighting is, both at home and at work. The eye has the ability to adapt to a wide range of illumination, but insufficient room illumination makes work difficult and can lead to accidents. Poor lighting also causes various eye diseases and blurred vision.

When performing most work, it is necessary to clearly see materials, products, and equipment. If we cannot look at an object well, it causes fatigue, overwork and headaches.

The eye can be compared to a camera. When light rays hit the eye, they penetrate inside the eyeball, which consists of the cornea, lens and intraocular fluid located between them. The area of the eyeball behind the lens is filled with clear aqueous humor through which rays pass to produce images on the retina, the concave part of the eye's chamber. The retina performs the same function as the light-sensitive film in a camera. Adequate lighting is needed for the following reasons:

· Focusing: The eyes are unable to focus on distant and nearby objects at the same time. When you have to change focus on objects located at a distance from each other, your eyes quickly get tired. This occurs in jobs such as quality control or assembly line work. In such cases, the work area should be very well lit, especially those areas that are located further away.

· Different vision: Different people have different vision. For some it is weaker. Moreover, the eye's ability to quickly adapt to objects at different distances deteriorates over the years. Many people need glasses at 40-50 years old. It is therefore especially important that the workplace of older workers is well lit.

Visual acuity test

· You can test your visual acuity by trying to read the text suggested above.

· If you have difficulty reading this text in sufficient lighting, you should see an eye doctor who may need to prescribe glasses.

Lighting requirements in the workplace include: good use light and at the same time avoiding blinding sunlight or other light sources.

Daylight

Artificial lighting is not as recommended as natural daylight, but daylight can vary depending on the time of year and similar conditions. Consequently, the required amount of lighting is determined regardless of the available daylight.

Sufficient lighting should illuminate the entire work area and should not obscure any part of the body or machine. This applies to both daylight and artificial lighting.

It is important to make the most of daylight. Materials must not be stored in such a way that they impede the flow of daylight. Windows must be clean both outside and inside. If the window faces a wall, then this wall should be painted white so that more daylight is reflected onto the work area.

In industrial plants, daylight can be increased by using roof windows. However, it is necessary to think about additional lighting, since sunlight may not be enough, depending on the time of year.

The interior walls of a factory building should be painted in light colors to make the best use of both sunlight and artificial lighting.

Recommendations for planning, location and shielding of computer equipment in office premises. Work with a dark monitor. And in general, the lighting should be a little more subdued than in other rooms.

Contrasting lighting

To distinguish objects with low contrast, you have to strain your eyesight. It is especially difficult to distinguish objects in semi-darkness. Moving from a brightly lit area to a darkened room can even be dangerous, as the eyes need time to adjust to the difference in lighting and partial loss of vision is possible.

On highways, harsh shadows can lead to accidents if there is insufficient lighting. This problem exists in many workplaces.

Reflection

Reflection is the property of a surface to cast light. The darker the surface, the less light it will reflect and the more light required to illuminate the room. Light reflected directly into the eyes may cause blinding.

A) Light blinding a worker due to a lamp hanging low from the ceiling.

B) reflected blinding light

The eyes adjust to the brightness of the light, in this case coming from a lamp or reflection. The pupil of the eye constantly contracts due to bright light. In the right picture, the eyes must constantly adjust to the reflection. In both cases, it is very difficult to look at the work material, which causes fatigue and headaches.

Bright light

Glare is caused by looking at light that is brighter than the eye can adjust to. This happens when the source artificial lighting without a lampshade, hanging too low or when sunlight is directed directly at the work area.

Reflective glare occurs when light bounces off shiny surfaces. This can be avoided by properly positioning the appropriate type of lamp.

Blinding occurs due to:

1. low-lying lamp hanging from the ceiling

2. incorrectly directed local lighting

3. reflected light

Lighting requirements

Basically, the light should fall on the materials or objects with which we are working. As a rule, the light source should be located behind and to the left, unless the person is left-handed. This applies to local lighting in the workplace.

Factors that determine the amount of light include:

the nature of the work being performed (for example, more light is required to perform precise work)

ability of surrounding surfaces to reflect light

· the size, shape and reflectivity of objects and whether the object is easily distinguishable from the surrounding background

· vision of workers.

Remember!

· Lighting problems are a combination of light sources, glare, reflection and obscuration. Good lighting requires lightly painted walls!

Questions:

· What can be done to make better use of the light coming through windows, doors and skylights?

· Don't you think that your room requires more artificial lighting in addition to natural lighting?

· How is the light positioned in relation to the workplace? Is there a darkening of the workplace?

· Do you have problems with glare from daylight? Are there glare lights?

· Is the workplace of older workers adequately lit?

Poor general lighting and lack of local lighting causes awkward posture and associated fatigue, and reduces productivity and quality of work. General lighting should ensure uniform distribution of light throughout the work area. The intensity of the light is determined by the nature of the work being performed. Stronger light is needed when performing work involving small parts during precision operations. Practice shows that there is only one way to fulfill this condition - installing local lighting. The color scheme of the room itself is very important. The floor, walls and ceiling should be painted in light colors.

General and local lighting

Typically, lighting in work areas is general or a combination of general and local lighting

· General lighting is provided by lamps on the ceiling or walls. General lighting illuminates the entire work area.

· Local lighting is lighting in the immediate vicinity of the workplace to illuminate objects.

· The combination of general and local lighting allows you to best illuminate the workplace.

Cleaning and maintenance of lighting fixtures

The amount of light received decreases as the light source ages. The most important reasons:

· wear and tear of the light source (lamps)

· dirty lighting fixtures

· dirty room

· Dirty reflectors or anti-glare devices.

The biggest cause of poor lighting is dirt on the lamps or lighting fixtures.

Fluorescent lamps and tubes age over time. After a certain period of time, they provide only half of the original light. Therefore, it is not enough to replace burnt out light bulbs. They all need to be replaced when there is not enough light in the room.

Burn out the fastest ordinary light bulbs, they also give the least amount of light. Their lifespan is typically 1,000 hours, compared to the 7,000 hours that fluorescent lamps last.

We can say that the contamination of lighting fixtures is determined by the work performed in a given room.

Even for economic reasons, lamps must be serviced regularly. The required illuminance standard is easier to achieve if lighting fixtures are kept clean and lamps are replaced.

Remember!

· It is important to maintain lighting fixtures regularly. This also makes it possible to think about how best to illuminate the premises.

Exercise:

· Who is responsible for keeping lamps and windows clean?

· If a lamp burns out, who is responsible for replacing it?

· Are there any special applications that require local lighting?

· Have any lighting improvements been adopted? Describe them.

Impact of noise

Not all sounds can be classified as noise. We call noise those sounds that we don't like.

IN recent years the noise level has increased. Equipment, which has become much more productive and speedy, has also increased the noise level. In large open work areas, noise is distributed throughout the area and can increase in intensity as additional equipment contributes to the noise level.

The perception of noise is always very individual, however, it is obvious that even hearing loss is possible, sometimes irreversible, if the noise level reaches too high levels.

Noise affects more than just hearing. Noise also affects blood circulation and creates tension in the body. After such phenomena, a person usually has trouble falling asleep. Noise can lead to:

· hearing impairment

Difficulty in communication between people

· irritation.

People perceive sounds differently. What you find pleasant and pleasing to the ear, others find noisy and unpleasant. Remember that any time a person is exposed to loud noise, permanent hearing loss can result.

Noise is an unpleasant sound

Noises that may cause injury

Some workplaces may experience noise levels that cause hearing damage. Often noise is created various types working equipment. Compressed air machines or hand anvils also make a lot of noise.

Continuous noise at a level of 85-90 decibels and above is dangerous to hearing. If a worker spends more than 5 hours daily in an environment with this level of noise, hearing loss can result. A sharp, unexpected loud sound in the immediate vicinity of the ear can also lead to hearing loss. Unfortunately, you cannot close your ears like you can with your eyes.

It is not just the direct exposure to noise that negatively affects humans. In stressful work situations, annoying or overwhelming noise can cause mental distress, which in turn can cause physical distress.

Drowning noise

Overpowering or drowning noise means that the sound we want to hear is difficult for other sounds to hear. In the workplace, noise from equipment can drown out the sound of passing cars or interfere with conversation. Similar problems exist in many industrial enterprises.

The sound level should not exceed 60-70 decibels if we have to have a conversation at a normal distance.

Annoying noise

Annoying noise can come in many forms. Our level of perception of noise as an irritant can be very subjective, depending on whether we want the sound or not. Even a low sound can cause irritation.

Questions and tasks:

· Does it happen at work that you can’t hear what others are saying?

· Discuss the sources of noise that bother you most in the workplace.

· Do you feel that sometimes the noise becomes so loud that it can damage your hearing?

Hearing damage

Working in an area with high noise levels for long periods of time can cause significant hearing loss. The ear is a very sensitive organ that needs to be protected.

The figure shows a cross section of the ear. The sound passes through the outer ear and causes the eardrum to vibrate in the three ear bones. The vibrations pass through a fluid contained in a tightly wound tube called a volute. The auditory nerve, which ends in the cochlea, transmits the signal to the brain.

When a person is exposed to strong noise, the cochlea is the first to suffer. The very thin endings inside the cochlea are destroyed and die. This damage is irreparable. Restoration is not possible.

Different people have different degrees of sensitivity to noise. Some people's hearing may be damaged more quickly than others.

The picture shows a cochlea damaged by noise. About 1/3 of the nerve endings are completely destroyed. This makes it impossible to perceive high tones—the hearing is damaged.

Partial hearing loss

We should know that there is such a warning signal: if after being in a noisy room we find ourselves in a calmer environment and at first we no longer hear faint sounds, this means our hearing has deteriorated - this is called partial hearing loss. This type of loss is recoverable. After some time of rest, your hearing will return to its normal level.

It is therefore important that those people who work in a noisy environment can take rest breaks in some quiet place. Partial hearing loss should serve as a warning. You cannot work in such a noisy place for many years without permanent hearing loss.

Disability

Hearing - important way perception, which helps people communicate with the world around them. With complete or partial hearing loss, it becomes difficult to hear what other people say or listen to messages on radio and television.

Complete or partial hearing loss can have the following consequences:

Difficulty understanding other people's normal speech

· it is difficult to understand what foremen or colleagues at work are saying and what kind of sound signals they give

· may suffer from a feeling of isolation because the person does not participate in conversations with colleagues during breaks or meetings with friends

· you have to take breaks and relax more often than usual, because you often need to expend all your energy to get work done.

Remember!

· The ear tolerates low sounds more easily than high ones. Consequently, when hearing is damaged, the perception of high-pitched sounds disappears most quickly. We may not notice this because we hear normal speech. It is only within a few years that hearing loss becomes so obvious that it becomes difficult for us to understand other people's speech.

Miners experience very high noise levels. In addition, their body vibrates so much that it affects blood circulation and causes damage to muscles and ligaments.

Vibration combined with noise

Noise may be due to vibration, flowing gases or liquids. Many powered machines or hand tools also transmit their vibrations to the human body. They can cause damage to muscles, ligaments and affect blood circulation. The most painful example of vibration-related injury occurs among workers who use pneumatic drills, saws, or jackhammers.

Whole body vibrations are also a big problem. An operator who sits on a vibrating seat for a long time or operates a sawmill is also subject to strong vibrations. In this case, the frequency of vibrations is much lower, although they are combined with low noise during engine operation. The vibrations experienced by an operator operating a sawmill cause significant disturbance as well as damage to internal organs.

Questions and tasks:

· Do you or your colleagues suffer from partial hearing loss or deafness?

· What problems can deafness cause? At work? Outside of work?

· The problem of hearing loss due to the noise of operating machines has long been known to us. What do you think about her? Do you perceive it as a necessary evil?

· What negative effects are possible when working in a very noisy environment? Make a list possible consequences for health and safety.

Decibels

The sound may consist of one pure tone, but most often it is a combination of many tones different levels(volume) and pitches (high and low frequencies). Noise level is measured in decibels. Pitch is measured in Hertz.

If we feel that a sound is disturbing, it is not because of the volume alone. Pitch is also a strong factor. High tones are more annoying than low tones. Pure sounds can cause anxiety and damage your hearing even more than complex tones.

The following table shows the decibel levels of various sounds. Decibels are most often used because they most closely represent the impact of noise on the ear.

Decibel scale characteristics

Noise from different sources mixes with each other. The overall noise level in any location increases as the number of noise sources increases. Due to the specific characteristics of the decibel scale, it is not possible to simply add up different noise levels. Two different noise sources, each with a noise level of 80 dB, together give a level of 83 dB, not 160 dB.

Another important characteristic is that changes from 80 to 83 dB are perceived by the ear as strongly as changes from 40 to 43 dB.

|

Impact on humans |

Noise level in decibels (db) |

Sound source |

|

Severe lesions |

Jet Rivet hammer |

|

|

PAIN THRESHOLD |

||

|

Defeat |

Airplane propeller Jackhammer Chainsaw Sheet rolling shop Heavy truck |

|

|

Danger |

Busy street |

|

|

Inability to hear speech |

Car |

|

|

Annoying |

Normal conversation Talk Quiet music on the radio Calm city apartment rustle of leaves |

A change of 3 dB, as in our example, always has the same effect on our perception of noise, regardless of the original noise level.

It is important to consider these facts when discussing noise intensity and the transition from one level to another. When we say that the noise level has dropped from 90 to 80 dB, this may not seem like much, but given the characteristics of the noise scale feature, this means that this reduction would have the same effect if we removed 9 out of 10 noisy machines from the shop floor.

Remember!

· if you feel that you cannot speak in a normal voice to the other person, being at arm's length from him, then the noise level is too high.

Questions and tasks:

· List the sources of noise that affect you.

· Can you name which machine parts or elements are the main source of noise?

· Is it possible to separate noisy work in your place from quiet work?

Ways to control noise levels

Equipment and production processes

Many noise sources produce and transmit sound, both through the air and through the structure of the machine. Thus, efforts should be made to reduce the noise level emanating from the equipment and spreading throughout the production area. It can be difficult to reduce noise levels from equipment and manufacturing processes without interrupting production or reducing output. However try:

· isolate the entire machine or a particularly noisy part of the machine

· maintain equipment regularly to keep it in order and thus reduce noise levels

Reduce vibration of components and upholstery

Replace metal parts with parts made of sound-absorbing material, such as plastic, rubber or other materials

· slow down the braking time of piston equipment.

A well-designed casing made of sound-absorbing material can reduce noise levels by up to 55dB. If the noise level in the workplace is above 80 dB, measures must be taken to reduce the overall background noise. This may include installing sound-absorbing covers around the machine or wearing personal hearing protection. It is preferable to use sound-absorbing covers around noise sources or other similar measures rather than earplugs. However, while improvements are being made, it is necessary, without waiting for their completion, to use personal protective equipment.

Noisy equipment

Noisy equipment can be made less noisy without any complex measures. You can do the following:

installation of a silencer at the outlet

· use of a different type of pneumatic equipment with fewer parts operating at high frequencies

· replacing equipment with a less noisy model, for example, fans with appropriate blades

good fit of noise-producing parts

· insulation or shielding of noisy equipment from the workplace.

Working with materials

The noise caused by the processing of materials can be greatly reduced. Avoid knocking on materials, especially when transporting equipment.

Also don't forget:

· reduce the height of storage of materials so that they do not fall from shelves or racks

· strengthen sheet metal structures that are overloaded with bags or materials, or cover them with sound-absorbing material

Reduce sharp impacts by using rubber or plastic coverings

· reduce the speed of the conveyor

· install several conveyor belts on conveyors to distribute the load and reduce speed.

There are other ways to reduce noise levels when transporting parts:

The conveyor belt can be raised and lowered using a hydraulic system. At the end of the belt there is a drum with rubber brake blocks attached to inside container. The drum rises automatically. The free fall height is always the same as the distance between the last block and the top level of material in the container.

Some factories use chutes for transporting materials made of sheet iron, plastic or wood. When the conveyed material hits the chute, a lot of noise is produced.

Noise can be reduced by covering the outside of the gutter with sound-absorbing material. When purchasing a new transport chute, choose this design.

The following example shows what measures can be taken to reduce the level of resonance, i.e. the sound that is amplified during contact with rims or wheels.

EXAMPLE. In an automobile manufacturing plant with multiple production lines, some lines are typically noisier than others. Let's say there is noise on the body grinding line high frequency, which distracts people working in the same room.

MEASURES. Place light barriers on both sides of the production line, and install a canopy of sound-absorbing material on top, which separates other workers from the noise produced during work. But you still need to use headphones when working in this area.

Workrooms

The spread of noise throughout the work area can be reduced if:

· cover the ceiling and walls with sound-absorbing material (porous)

· use noise-absorbing screens

· install a noise control zone and rest rooms.

Installing sound-absorbing material on the ceiling reduces general level noise in the room. The sound-absorbing partition on the ceiling can be replaced with panels.

If noise sources are isolated by a wall or protected by a cover, the noise level can be reduced both near the noise source and at a distance from it. Then those people who work with quiet equipment in quiet work are not distracted by the noise around them.

The spread of noise throughout the room can be reduced and the noise level reduced if the ceiling and walls are covered with sound-absorbing material.

It is often necessary to place noise-producing equipment on elastic mats or stands. This isolates vibrations and also prevents them from spreading through the building structure, pipes, etc. Large, heavy machines should be placed on their own foundation, separate from the floor of the entire workshop.

Remember!

In practice, a combination of several noise reduction methods is usually used:

Reducing overall background noise

Isolating the Noise Source

Sound-absorbing materials.

Often, reducing the noise produced becomes an expensive endeavor, so other methods must be used. For example, you can try to use barriers made of porous material.

Questions:

· How can you tell if your workplace is too noisy?

· Have you applied any of the suggestions made in this section to your equipment?

· What measures can you take now to reduce the source of noise?

Hearing protection

Headphones, earplugs

Noise, which may be hazardous to health, is reduced through technical measures. If this is not possible, then it is necessary to use personal protective equipment, for example, you can use headphones or earplugs.

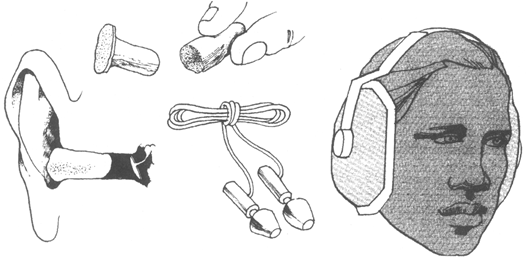

Earplugs used.

L. Bata - acoustic fibers.

2. Plastic-coated acoustic fibers.

3. Elastic plastic.

4. Reusable plastic earplugs.

It is important that earmuffs are worn at all times while a person is exposed to high noise levels; even if a worker removes them briefly, this still poses a serious threat to hearing.

Remember!

· If headphones or earplugs must be used, they must be carefully checked to be effective and must fit snugly. Keep in mind that if headphones or earplugs do not fit snugly, they are not protecting your ears. Earplugs should be regularly cleaned, repaired and replaced as necessary. Achieving consistent use of hearing protection requires collaboration between craftsmen and workers.

Questions:

· Do you have noise protection devices at your disposal?

· If yes, are they used? Are they cleaned regularly?

· Don't you think there are jobs that require the use of noise protection?

· Why do many workers not like to use these tools?

USEFUL TIPS

Heat and ventilation

· There is sufficient natural ventilation through windows and open openings.

· Radiation from the roof and walls is kept to a minimum by using suitable material and colour.

· There is good ventilation on the roof and ceiling.

· There are sufficient fans to keep the air always clean and pleasant.

· In hot shops, air circulates using fans.

· Hot surfaces are isolated and kept at a distance.

· There is a barrier between workers and heat sources.

· Heat-protective aprons or clothing are used where necessary.

· When using air conditioners, a suitable type is used, taking into account air pollution during the production process.

· Avoid hypothermia and drafts caused by air conditioners.

· Heavy physical labor should be avoided in hot areas.

· Avoid working in confined spaces at high temperatures.

· When working in a hot place, take the required number of breaks.

· There should be cool drinking water near the workplace.

Lighting

· The workplace receives enough daylight, not darkened and falling correctly.

· A glazed roof is used to increase light.

· Light colors are used to paint the walls.

· There is no glare from ceiling lamps or local lighting lamps.

· Avoid glare due to strongly reflected light.

· Avoid very contrasting shadows.

· General lighting is appropriate for the type of work being performed.

· Local lighting is used as an auxiliary lighting, in addition to the general one, especially for precision work.

· All lamps are replaced regularly.

· Lamps and fittings are cleaned regularly.

· Noisy parts of machines are protected or completely covered.

· To avoid noise during operation, machines are regularly tuned.

· Sound-absorbing material is used for the ceiling, walls and car covers.

· Noisy equipment or parts are replaced with modern models.

· A protective screen is used to prevent the spread of noise.

· The height of objects in containers is kept to a minimum to avoid sound reflection over long distances.

· Workers working on quieter equipment are not exposed to noise from other machines.

· Workers in the noisiest areas are more likely to be moved to other work areas to avoid being exposed to noise for too long.

· Whenever possible, the transmission of vibrations from machines to the worker’s hands is reduced.

· When the noise reaches 85-95 dB, use headphones.

Hygienic standards for microclimate parameters in the work area are given in GOST 12.1.005 - 76. A work area is considered to be a space up to 2 m high above the floor or platform on which the workplaces are located. A permanent workplace is considered to be one where the worker stays for more than half of his working time or more than 2 hours continuously. If people work in different places of the work area, then consider it all as a permanent workplace.

The microclimate in the work area is determined by the combinations of temperature, humidity and air speed acting on the human body, as well as the temperature of the surrounding surfaces. High humidity makes it difficult for the body to transfer heat through evaporation at high air temperatures and contributes to overheating, and at low temperatures, on the contrary, it enhances heat transfer, promoting hypothermia. The optimal microclimate parameters are those that, with prolonged and systematic exposure to a person, ensure the preservation of the normal functional and thermal state of the body without straining thermoregulation reactions, which creates a feeling of thermal comfort and serves as a prerequisite for high performance. Maintaining an optimal microclimate is only possible if the enterprise is equipped with microclimate conditioning units. In other cases, acceptable microclimatic conditions should be ensured, i.e. those in which, although tensions in the body’s thermoregulation may occur, they do not go beyond the limits of its physiological adaptive capabilities. In this case, there are no health problems, but there may be a deterioration in well-being and a decrease in performance.

Hygienic standards depend on the category of work in terms of the degree of physical activity, as well as on the warm or cold period of the year and on excess sensible heat entering the equipment room, heated materials, heating devices, people and sunlight, i.e. from the difference between sensible heat and heat loss when calculating outdoor air parameters, taking into account all measures to reduce heat loss. Excess heat is considered insignificant if it is no more than 23 J/(m3 x s), and if more, then the room is classified as a hot shop.

For example, for light work in the warm season optimal temperature is equal to 22...25 ° C, and the permissible one (with significant excesses of sensible heat) is 5 ° C higher than the average outside air temperature at 1 pm of the hottest month, but not higher than 28 ° C. Relative humidity is up to 55%. Air speed 0.2...0.5 m/s (optimal speed 0.2 m/s). During the cold period of the year at the same work, the optimal temperature is 20... 23 °C, the permissible temperature is 19... 25 °C. In some cases, certain deviations from the norms are allowed. A recording thermograph type M-1B measures air temperature, and a psychrometer measures humidity.

Rice. 26. Psychrometers:

a - Assman; b - Augusta; 1 - dry thermometer; 2 - fan head; 3 - wet thermometer; 4 - air channel; 5 - damp cloth

The psychrometer (Fig. 26) consists of a dry and wet thermometer. Relative humidity is determined from tables depending on the difference in thermometer readings. For the same purposes, recording devices-hygrographs of type M-2I, hot-wire anemometers of type EA-2M, etc. are used.

Anemometer measures the speed of air flow: vane (Fig. 27, a) - from 0.5 to 10 m/s, cup (Fig. 27, b) - from 1 to 20 m/s. A vane anemometer has a light wheel with blades mounted at an angle on an axis, which is connected by a worm gear to a pointer rotation mechanism. The wheel axis is parallel to the air flow. The air speed is determined according to the graph (located in the device passport) depending on the ratio of the readings from the anemometer and the stopwatch turned on at the same time.

Rice. 27. Anemometers:

a - winged; b - cup; 1 - wing; 2 - handle; 3 - revolution counter; 4 - cup