Penetrating solution Penetron is an excellent protection for concrete buildings, providing them with 100% waterproofing. Let's take a closer look at all the properties and methods of working with Penetron, as well as what effect this product has on concrete.

Concrete structures and surfaces finished with plaster are covered with waterproofing. Waterproofing eliminates many problematic issues. For example:

- It is possible to revive the water-repellent ability of concrete walls. Penetron can do this. It easily penetrates into the concrete, filling all its microcracks, and rewards with excellent water resistance.

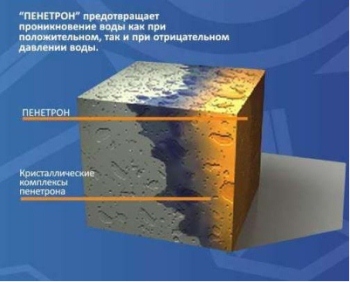

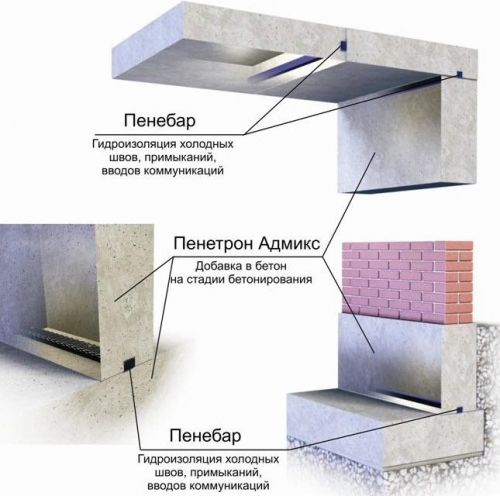

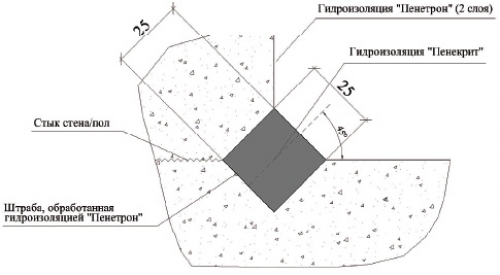

- It is possible to protect particularly vulnerable areas: joints, seams, chips, crevices. Penetrating waterproofing Penetron copes with this together with the additive Penecrit, which is applied to problem areas, increasing their resistance to moisture, before covering with Penetron.

- The flow that arose due to the intense rise of underground flows stops. Here, a solution made from Penetron and waterplag or Penetron and peneplag is used.

Scope of application.

Scope of application. The penetrating waterproofing mixture of this brand is used not only to protect concrete structures from water, but also from various chemicals, which are destructive: carbonates, nitrates, sulfates, chlorides. This will allow the treated structure to serve intact and intact for many decades.

Penetrating waterproofing solution Penetron is used for protective sealing of drinking wells, as well as other containers with water suitable for drinking. The composition of penetrating waterproofing of this brand includes cement and quartz sand with an admixture of special environmentally friendly additives that do not cause any harm to others. Therefore, these products can be used to treat any structures made of concrete.

Qualitative characteristics

- Since penetrating waterproofing mixtures interact with wet concrete, this makes the work much easier and saves money, because the building material does not need to be pre-dried.

- Working with Penetron is quite easy. To cover a concrete surface with it, you don’t need any special skills. You just need to carefully read the instructions for the composition and perform all the indicated manipulations correctly.

- Waterproofing can be applied to the walls of the structure both outside and inside. This will not change the functional qualities of the solution.

- Concrete treated with Penetron additive will significantly increase resistance to moisture and sub-zero temperatures. In this case, the structure will gain greater strength, but will not lose vapor permeability.

- If somehow the waterproofed surface is damaged, this will not reduce the level of its water resistance, because the properties of the treated material can be regenerated.

- If the solution in question is mixed with another composition of the same series, a house or other structure covered with such a mixture will withstand any aggressive environment.

- This composition successfully interacts with any type of concrete mixtures, protecting not only the concrete, but also the internal metal structure, acting as reinforcement.

- The penetrating agent of the Penetron brand is an environmentally friendly material.

Advantages of the composition

Among the positive features of Penetron are the following:

Among the positive features of Penetron are the following:

- It is impossible to damage the coating made from this product, since the solution is absorbed into the concrete and is destroyed only when the concrete structure itself disintegrates. But this will not happen soon, since the waterproofing agent reliably protects the building from external negative factors.

- When using waterproofing from this company, the material being treated does not need to be thoroughly dried. Since the product can be applied from any side, to waterproof the foundation there is no need to free it from the soil.

- The mixture slowly improves water resistance building material up to 2 MPa and beyond. This was discovered during a moisture resistance test of concrete coated with Penetron. The results showed that from W4 to W10 it increases in 28 days. And from W14 to W20 - in three months.

- This waterproofing agent does not have any harmful effects on the building mixture. Concrete structures treated with Penetron retain all their positive characteristics. Including vapor permeability.

Operating principle

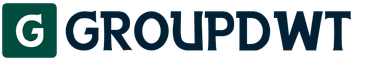

On the surface of concrete coated with Penetron, increased chemical reaction. At the same time, small revolutions of chemical action are observed inside the material. Therefore, the product exerts one-sided diffuse pressure, due to which the solution particles penetrate deep into the concrete, thereby equalizing the force of chemical processes.

Note that the higher the humidity level of the treated surface, the better, the faster the particles of the protective solution penetrate into the material.

Inside the building material, the active substances of the waterproofing agent are broken down in the liquid present inside the concrete, thereby interacting with aluminum and calcium ions, as well as with salts and metal oxides. These processes contribute to the development of salts of a different kind that react with water, thus forming non-cleavable crystalline hydrates. They cover the entire free internal space of the building material, becoming one with it.

Cells, as well as other free microscopic spaces of concrete filled with waterproofing crystals, do not absorb moisture, since the forces of surface tension of water begin to function. The crystalline structure inside the building material prevents liquid seepage even during increased hydrostatic conditions.

The speed of the processes described above is influenced by many factors: the level of porosity, density of building materials, degree of humidity and temperature indicators external environment. If the liquid evaporates, the crystallization of Penetron will stop. When the humidity level increases, for example during precipitation, the proliferation of crystals inside the concrete is restored. This process is called "self-medication" concrete mixture.

Preparation of the product

To prevent the solution from thickening, it is stirred from time to time during the work process.

To prevent the solution from thickening, it is stirred from time to time during the work process. To properly prepare the solution, you need to combine the dry waterproofing agent and water according to the recipe. By stirring, achieve homogeneity of the mixture. The consumption is 1:2, that is, part water to two parts waterproofing admixture. For example, for 1 kg of Penetron, 400 grams of liquid are consumed.

You need to dilute the solution by pouring water into the dry mixture, and that’s the only way. Stir for two minutes with your hands or a drill at low speed. As a result, you should get a creamy mixture. You need to make the amount of solution whose consumption will end in a maximum of half an hour. In order to maintain the original thickness of the mixture, it must be constantly shaken.

Surface preparation before application

Initially, problem areas of concrete are prepared: seams, joints, cracks, places of communication. In these areas, grooves are made 2.5 cm wide and deep. Then the grooves are laid with a thick concrete mixture. The next step is to clean the surface from various coatings to bare concrete. Paints, tile residues, cement laitance, and various oil-based contaminants are removed.

Next, chemical treatment of the surface is carried out by applying a weak acid composition, which is then thoroughly washed off with a large volume of water. At the last stage of preparation, it is necessary to water the surface. A large volume of water is used to ensure that the object being treated is thoroughly wet.

Application of waterproofing

Apply first from side to side, and then from top to bottom.

Apply first from side to side, and then from top to bottom. If the waterproofing mixture is made, the surface is prepared, you can begin the processing process. Let us remind you that a diluted solution is good for half an hour, so prepare it based on this consumption.

The maximum consumption of waterproofing agent depends on the total volume of the object being treated. As a rule, at least 800g of dry Penetron is consumed per 1m3. This needs to be taken into account if you have chosen a dry variation of Penetron.

Waterproofing of objects is carried out as follows:

- The first ball of solution is applied to the pre-moistened surface using a sprayer or a brush with artificial hairs. Try to coat the entire wall without missing a millimeter. Pay special attention to joints and other difficult places.

- Wait for the first ball to harden, then wet it with water and apply the next level of waterproofing. If you carry out the procedure with a brush, then when applying the second layer, move the brush perpendicular to the previous ball. That is, if at first you “painted” from side to side, now you need to paint from top to bottom, and vice versa. This will help achieve the desired effect with minimal consumption of material. But a sprayer is more economical, because the hairs of the brush tend to absorb the product.

How to care for a waterproofed surface?

“Freshly painted” objects should be carefully protected for three days from sub-zero temperatures and mechanical factors. During this time, you need to constantly moisturize the surface, make sure that there are no cracks or peeling. Moisten the desired object using a sprayer, as well as wrapping the surface in polyethylene. If a part is being treated that will be in constant contact with water, the moisturizing time should be extended to 14 days.

Precautions

All manipulations are carried out with rubber gloves and safety glasses, since one of the components of the solution is Portland cement, which tends to irritate the mucous membranes and skin. If the solution comes into contact with skin, rinse the area thoroughly with water.

Dry mixture for waterproofing concrete surfaces TU 5745-001-77921756-2006

Description of penetrating waterproofing Penetron

Attention! For waterproofing cracks with an opening width of more than 0.4 mm, seams, joints, interfaces, abutments, and service entries, Penecrit is used in combination with Penetron.

Advantages of penetrating waterproofing Penetron

Why is penetrating waterproofing today the most progressive and technologically advanced method of protecting concrete from the harmful effects of water?

- Penetrating waterproofing is not subject to mechanical wear, since concrete itself has waterproofing properties. The service life of waterproofing is equal to the service life of concrete, and due to waterproofing of concrete, this period increases.

- The use of penetrating waterproofing is more technologically advanced. There is no need to completely dry the concrete. Thanks to the penetrating properties of Penetron, the concrete structure can be processed from any side, in other words, when processing the foundation there is no need to dig it out.

- Penetrating waterproofing Penetron has unique properties of self-healing through cracks and pores and other defects that inevitably appear on any concrete structures during operation, with an opening of no more than 0.5 mm. If water begins to seep into the newly formed pores of concrete, crystal growth resumes.

- Penetron gives a gradual increase in the water resistance of concrete to W20 (2 MPa) and higher, for example, when testing the water resistance of concrete samples with the waterproofing additive Penetron with the effect of self-healing of cracks, the water resistance grade increases from W4 to W10 after the next 28 days and from W14 to W20 in within 90 days.

- Penetron does not affect the basic physical parameters of the concrete mixture: mobility, strength, setting time, etc., with the exception of water resistance. Concrete treated with Penetron retains vapor permeability.

The branded material Penetron will help even in conditions where other dry building mixtures cannot cope. So, as already noted, the operation of the branded waterproofing material Penetron is based on a completely different principle. Typically, waterproofing is superficial. By applying surface waterproofing materials to the concrete plane, we create a certain protective layer that prevents the penetration of water.

Operating principle of penetrating waterproofing Penetron

When applied to wet concrete liquid solution of material for penetrating waterproofing "Penetron" a high chemical potential is created on the surface, while the internal structure of the concrete retains a low chemical potential. Osmosis tends to equalize the potential difference; osmotic pressure occurs. Due to the presence of osmotic pressure, the active chemical components of the Penetron material penetrate deep into the concrete structure. The higher the humidity of the concrete structure, the more effective the process of penetration of active chemical components into the depths of concrete. This process occurs under both positive and negative water pressure. Penetration depth of active chemical components of the Penetron material a continuous front reaches several tens of centimeters.

Unique properties of penetrating waterproofing

Penetrating materials of the Penetron system have a number of unique properties that make their use as simple and effective as possible.

- Penetron materials are applied to a damp surface; pre-drying of the surface is not required, which significantly reduces the cost of work

- technology for performing waterproofing work using Penetron system materials does not require a complex, time-consuming and costly surface preparation procedure

- Penetron system materials are easy to use

Chemical resistance of concrete after applying penetrating waterproofing

Chemical resistance and anti-corrosion properties of concrete after using Penetron penetrating waterproofing.

Testing of penetrating waterproofing material Penetron

The action of the Penetron material is based mainly on osmotic pressure, reactions in the solid state and Brownian motion. The chemical components of the dry mixture "Penetron", dissolving in water, penetrate deeply into the structure of concrete and react with components cement stone hardening products.

The action of the Penetron material is based mainly on osmotic pressure, reactions in the solid state and Brownian motion. The chemical components of the dry mixture "Penetron", dissolving in water, penetrate deeply into the structure of concrete and react with components cement stone hardening products.

The use of the Penetron mixture contributes to the durability of concrete and reinforced concrete structures, since by reducing the permeability of cement stone to aggressive environments, their service life increases.

VIDEO INSTRUCTIONS

Instructions for use of PENETRON materials

Attention! Waterproofing work should be carried out at a temperature not lower than +5 °C.

SURFACE PREPARATION

Clean the surface from dirt to structurally sound concrete. Important! Before applying Penetron system materials, moisten the concrete with water until it is as saturated as possible.

PREPARATION OF MORTAR MIXTURE

Attention! To prepare the mortar mixture, use only clean containers and water. Prepare the amount of mortar mixture that can be used within 30 minutes (5-7 kg of dry mixture). Optimal temperature mixing water 20 °C. When the water temperature decreases, the setting of the mortar mixture slows down, and when it increases, it accelerates. Mix the Penetron dry mixture with water in the proportion of 400 ml of water per 1 kg of dry mixture or 1 part water to 2 parts dry mixture by volume. Mix the mortar mixture for 1-2 minutes by hand or using a low-speed drill until a liquid, creamy consistency is obtained. Attention! Stir the mortar mixture regularly during use to maintain the original consistency. Adding water to the mortar mixture is not allowed.

APPLICATION

Apply the Penetron mortar mixture with a brush or sprayer for mortar mixtures evenly over the entire surface in two layers without gaps. Apply the first layer to wet concrete, the second to the fresh, but already set first layer. Before applying the second layer, moisten the surface. Attention! Insulate all cracks, seams, joints, communication entries, interfaces and connections with Penecrit mixture. If there are leaks, fix them with quick-setting Peneplag or Waterplug mixtures.

DRY MIXTURE CONSUMPTION

0.8-1.1 kg/m2.

CARE OF TREATED SURFACE

Protect treated surfaces from mechanical influences and negative temperatures for 3 days. Make sure that the treated surfaces remain damp for 3 days, for which use water spray and/or covering the concrete surface with a moisture-proof film.

APPLICATION OF DECORATIVE COATING

It is recommended to apply finishing materials to the surfaces of structures treated with Penetron system materials 14 days after treatment. The holding time can be reduced or increased depending on the requirements of a particular type of finishing material for maximum permissible humidity concrete. Attention! Before applying decorative coating, surfaces treated with Penetron system materials must be thoroughly cleaned mechanically to improve adhesion.

PRECAUTIONS

During work, it is necessary to use personal protective equipment: chemical-resistant rubber gloves, cotton gloves, a respirator, goggles, protective clothing made of thick fabric, rubber boots. If the mixture gets on your skin or eyes, rinse immediately with water and consult a doctor.

TRANSPORTATION

Accepted by all modes of transport.

STORAGE CONDITIONS

Storage is allowed at any humidity and temperature from -60 to +50 °C.

GUARANTEED STORAGE LIFE

18 months from the date of production, provided that the seal of the original packaging is intact.

Dosing error is no more than 1 ℅.

Technical characteristics of penetrating waterproofing Penetron

| No. | Material characteristics | Meaning | Measurement methods |

|---|---|---|---|

| 1 | Appearance |

Free-flowing gray powder without lumps or mechanical impurities |

TU 5745-001-77921756-2006 |

| 2 | Humidity, %, by weight, no more | TU 5745-001-77921756-2006 | |

| 3 |

Setting time, min.: |

TU 5745-001-77921756-2006 | |

|

start, not earlier |

|||

|

end, no later |

|||

| 4 | Bulk density in standard uncompacted state, kg/m3 | TU 5745-001-77921756-2006 | |

| 5 | Increasing the waterproof grade of concrete after treatment, steps, no less | TU 5745-001-77921756-2006 | |

| 6 | Increase in compressive strength of treated concrete from initial treatment, %, not less | TU 5745-001-77921756-2006 | |

| 7 | Increasing the frost resistance of concrete after treatment, cycles, not less | GOST 10060.1-95 | |

| 8 | Resistance of concrete after treatment to acid solutions: HCl, H 2 SO 4 | Art. SEV 5852-86 | |

| 9 | Resistance of concrete after treatment to alkalis: NaOH | Art. SEV 5852-86 | |

| 10 | Resistance of concrete after treatment to the action of light and dark petroleum products | Art. SEV 5852-86 | |

| 11 | Resistance of concrete after treatment to gamma irradiation with a dose of 3000 Mrad | Conclusion of VET "Progress" No. 22/26 from 05/06/03 |

|

| 12 | Ultraviolet |

has no effect |

Art. SEV 5852-86 |

| 13 | Applicability for drinking water tanks |

allowed |

Hygienic certificate TU 5745-001-77921756-2006 |

| 14 | Acidity of the application environment, pH | Art. SEV 5852-86 | |

| 15 | Application: surface temperature, ° C, not less | TU 5745-001-77921756-2006 | |

| 16 | Operating temperature, ° C |

in accordance with concrete exploitation standards |

TU 5745-001-77921756-2006 |

| 17 | Material storage conditions |

in rooms of any humidity at temperatures from - 80 to +80 o C |

TU 5745-001-77921756-2006 |

| 18 | Guaranteed shelf life of the material, months, not less |

TU 5745-001-77921756-2006 |

MANUFACTURER WARRANTY. Factory waterproofing materials Penetron guarantees compliance materials for penetrating waterproofing of the Penetron system Technical Conditions 5745-001-77921756-2006 “Mixtures of dry waterproofing dispersed systems Penetron”, as well as all modern standards. The Penetron waterproofing materials plant guarantees that the Penetron system materials contain all components in their appropriate proportions. The use of Penetron system materials must be carried out in strict accordance with Technological regulations on pr The use of penetrating waterproofing materials of the Penetron system.

Scope of application of penetrating waterproofing Penetron

PURPOSE

PURPOSE

It is used for waterproofing concrete and reinforced concrete structural elements by increasing their water resistance, and the concrete acquiring the property of “self-healing” cracks with an opening of up to 0.4 mm.

PECULIARITIES

The Penetron mortar mixture is applied to a thoroughly cleaned and moistened concrete surface from the inside or external sides structures regardless of the direction of water pressure. The use of the Penetron dry mixture prevents water from penetrating through the concrete structure with cracks opening up to 0.4 mm. "Penetron" allows you to protect concrete from the effects of aggressive environments: acids, alkalis, sewage and groundwater, sea water. Concrete treated with the Penetron mortar mixture becomes resistant to carbonates, chlorides, sulfates, nitrites, as well as bacteria, fungi, algae and marine organisms. The use of dry mixture "Penetron" allows you to increase the frost resistance and strength of concrete. Concrete treated with Penetron mortar mixture retains vapor permeability. "Penetron" is environmentally safe and approved for use in domestic and drinking water supplies.

Preface. Water has always been and will be in the earth. It is represented by groundwater, as well as filtration water. In addition, the earth has a certain level of moisture that is inherent to it. All these are factors that influence the foundation. If you don’t think about protecting it, the destruction of the foundation will happen quite quickly.

Structural waterproofing technology

There are several methods of waterproofing strip foundation, which will help create protection for the foundation of the house. One of them is a drainage device. Thanks to the drainage system, moisture is removed from the building.

Another way to waterproof a foundation is to carry out high-quality foundation treatment. Waterproofing prevents water from entering the foundation. When waterproofing, it is advisable to adhere to high quality standards so that it lasts “for centuries”.

If a cause for concern for you is a damp basement or walls that are slowly starting to become damp, then there is no need to rush to conclusions about why this is happening. It is quite possible that the issue is not due to improper pouring of the foundation. Penetrating waterproofing Penetron will help you get rid of dampness.

What is Penetron penetrating waterproofing used for?

After a number of tests, it was proven that Penetron is harmless to humans and environment, it can be used in construction and creating water supply. Concrete after treatment with Penetron will not allow water to pass through it even under hydrostatic pressure and will be protected from aggressive environments.

![]()

Application of penetrating waterproofing

Penetrating waterproofing Penetron is a material designed to protect various concrete structures and buildings from the harmful effects of water. Wherever it is erected, this or that structure will always be in contact with water. Foundations are especially susceptible to getting wet.

For protection and long-term operation, it is necessary to waterproof the foundation with your own hands according to the instructions. The issue of waterproofing strip foundations should be approached with all seriousness. Do not forget that the foundation is the foundation of the house.

Technical characteristics of Penetron waterproofing

Specifications penetrating waterproofing Penetron

The deep penetration composition Penetron is used for waterproofing concrete, reinforced concrete structures and cement-sand layers of plaster of a grade of at least M150. Penetron is applied to thoroughly moistened surfaces, previously cleaned of materials that prevent the penetration of mixture components into concrete.

Modern construction teams very often turn to Penetron waterproofing for help. It is available in dry form construction staff, consisting of a specialized albolite, quartz sand with particles of a certain diameter, with a chemical admixture of modified elements. Its main purpose is to waterproof the surface of a concrete and reinforced concrete structure being built. Thanks to Penetron, the building is not afraid of moisture and exposure to water, and its strength and frost resistance increases. And chemical additives, in turn, provide active resistance in case of ingress of alkali, acid, sewage and groundwater, as well as if there is contact with sea water. The article will focus on penetrating waterproofing "Penetron"

Scope of application of Penetron waterproofing

- "Penetron" can be used as a stand-alone insulation or used in combination with auxiliary mixtures of the same series. It all depends on the type of construction.

- Such waterproofing is carried out when the surface has cracks 0.4 mm wide, and if they are larger, it is necessary to additionally use Penecrit. Thanks to the combined use of these compositions, it is possible to remove capillary suction (if the waterproofing is damaged), get rid of cracks, wide seams and joints, mating and abutting. And in order to eliminate pressure leaks, Penetron is used in combination with Peneplag and Waterplug.

- The main advantage of such a mixture is its environmental and radioactive purity. That is, after carrying out all the required checks, Penetron showed that it is absolutely harmless to the environment and to people. It has a certificate indicating that it can be freely used in construction, as well as for creating domestic and drinking water supplies.

- During its development, such a property as a rigid barrier to moisture was obtained. That is, concrete blocks will not allow water to pass through them, even at high hydrostatic pressure. Penetron is also used to protect concrete and from aggressive media (acids, water with increased level salt content, waste water, etc.).

Advantages of Penetron

- The mixture itself does not lose its warranty period. The duration of its operation is directly related to the base that was treated with it. And since it imparts additional waterproofing properties, this design will last even longer.

- Convenient application technology. Due to its penetrating properties, it can only be applied on one side. In addition, Penetron waterproofing does not require mandatory drying of concrete.

- It has, in fact, a unique property - self-healing. That is, if cleavages, micropores or other similar damage (with a diameter and depth of up to 0.05 cm) are formed in a concrete block, the growth of crystals is initiated, which fill the entire space. This happens the moment the solution comes into contact with water.

- "Penetron" increases the level of water resistance of the structure. This indicator is designated by the letter W. After applying waterproofing, within a month the indicator increases from 4 to 10, and if you wait 3 months, the concrete block will have an indicator of 20W.

- The composition only affects contact with moisture, otherwise the concrete retains its original characteristics. Impregnating waterproofing does not in any way affect the vapor permeability of concrete structures.

Advice: there are fakes of the original brand on the market, so before buying Penetron waterproofing, it is recommended to ask for quality certificates.

Operating principle of penetrating waterproofing "Penetron"

- The waterproofing is diluted to the required consistency, after which it is applied to the moistened concrete surface. For the best effect, it is necessary that the concrete surface is as wet as possible.

- The chemically active components of Penetron, penetrating deep into the concrete, react to the presence of ionic compounds of calcium and aluminum, metal oxides and salts, which are part of the composition of the concrete mixture. After which, upon interaction with liquid, crystalline hydrates are formed, which no longer dissolve. It is a network of such formations that combats concrete defects, forming one whole with the concrete structure.

- At the site of filled cracks and pores, surface tension forces of liquids act, as a result of which water simply does not move.

The rate at which crystals form and how deeply they penetrate into the concrete structure depends on several factors:

- concrete density;

- concrete porosity;

- humidity and temperature values of the environment.

The main component on which the stopping or construction of such chemical crystals directly depends is water. If it is there, then the process continues, but if it is absent, it stops.

Properties of penetrating waterproofing "Penetron"

- Since Penetron works with a wet surface, costs that would otherwise be spent on drying concrete are significantly saved.

- Application of this waterproofing does not require any specific skills or abilities. The sequence of actions is described in the instructions on the package.

- It does not matter on which side the concrete base will be covered with Penetron - from the outside or from the inside. It will act the same in both cases.

- Concrete treated with this waterproofing will increase its characteristics in terms of water resistance, strength and frost resistance. At the same time, the design retains its old parameters for vapor permeability.

- If for some reason the surface is damaged, this will not affect its acquired waterproofing properties.

- Concrete with “Penetron” acquires a new property - “self-healing”.

- This material does not wash out over time.

- If you use an additional additive of the same system of materials, for example “Penetron Admix”, then the surfaces will not be at all afraid of exposure to aggressive environments.

- For such waterproofing, it does not matter what brand of concrete you have to deal with. In addition, protection extends not only to the concrete itself, but also to its reinforcing components.

- "Penetron" is an environmentally friendly material, which is why it is often used to build drinking water tanks.

How to properly prepare the surface?

- Before applying the solution, the concrete surface must be clean. Therefore, it is cleaned of any contaminants - sand, dust, gunite. To do this, you can use special installations that supply a stream of water under high pressure. Or manually using a wire brush. If there is a paint coating, it must also be removed.

- When the concrete has a smooth and even surface, all remaining fatty deposits can be removed with a weak acid solution left for an hour. Then rinse with water.

- It should be remembered that Penetron waterproofing only works with a damp surface, and the moisture must saturate the entire structure of the concrete.

Formula for preparing the Penetron mixture

- In order to create a high-quality mixture, you should adhere to the following proportion: 1 kg of waterproofing goes to 0.4 liters of water.

- To ensure proper mixing of the consistency, water must be poured into the dry mixture, and not vice versa. Mix the substance with your hands or a drill for 1-2 minutes. Ultimately, the waterproofing should be liquid, similar in thickness to sour cream.

Experts recommend preparing the amount of solution that can be applied within half an hour. And when finished, prepare more mixtures. To prevent Penetron from thickening, it is stirred from time to time during operation.

If the waterproofing thickens, under no circumstances should it be re-diluted with water. It is necessary to re-prepare a “fresh” composition.

Waterproofing "Penetron" technology

- After the structural elements have been cleaned of dirt and the mixture has been prepared in the required quantity, you can begin the processing process itself.

- To do this, you need to have a brush made of synthetic fibers or a sprayer. Waterproofing is applied to the surface in two layers.

- As already mentioned, work is carried out only with wet concrete. Therefore, the first layer is applied immediately after the surface has been moistened. And they give some time for the composition to “grab” with the concrete. After which they immediately begin the second layer, but before that the surface is again moistened with water.

- It is important to ensure that both layers evenly cover the structure and do not leave any gaps or gaps. The average consumption of dry mixture for smooth surfaces will be 0.8-1.1 kg/m2, and if there are significant irregularities, this figure will increase.

- If pores, seams, joints are detected, as well as at the junctions of block structures, it is necessary to apply “Penecrete”, which isolates them. But in case of a leak - “Peneplag” or “Ventirplag”.

Waterproofing "Penetron" of technological openings and pressure leaks

When building houses, panel formwork is used for foundations and walls. They, in turn, leave behind gaps that should also be eliminated. “Penetron” and “Penecritus” can serve just for this purpose.

- The first step is to remove the plastic sleeve, which can be done using a drill. Next, the resulting hole is cleaned of dust.

- After which, using polyurethane foam, the gap is filled, but it is important that the edges remain free on both sides by about 2-2.5 cm. The walls of the resulting cavities are moistened with water, after which the hole is filled with “Penecrete”. The mixture is applied with a spatula or by hand. But in the second case, you should remember your safety and protect your hands with gloves. The solution itself should “sit” tightly in the cavity.

- After “Penecrete” is in its place, “Penetron” is applied on top of it, using a brush, at a rate of 1 kg per cubic meter. For the right effect, two layers are used.

- In a similar way, places where there is a leak are eliminated. Only in this case mixtures of Peneplag and Waterplag are used. They are pressed tightly into the hole where the leak is coming from. These materials have a high degree of adhesion. The speed of adhesion of the material to the surface of the hole is largely influenced by the temperature of the water and concrete - the lower it is, the slower the process.

- If the leak leaks through vertical cracks, then work is carried out in the direction from top to bottom.

- The resulting patches are processed on top with Penetron, but professional builders note that Peneplag is additional protection doesn't need it. But such savings are not always advisable, since the price of Penetron waterproofing is low, on average it is 300 rubles / kg.

Application of penetrating waterproofing on brick and stone surfaces

- “Penetron” is inherently a rather unique waterproofing product. It works not only with concrete, but also with brick and stone. But in the case of such an application, some features should be taken into account.

- Initially, the working surface must be plastered. For this purpose, only those cement-sand mortars are suitable that have a grade of at least M150 and in no case should you use gypsum plaster or lime mortar.

- Initially, a masonry mesh with a cell size of 50x50 mm or 100x100 mm is fixed to the surface. The plaster layer is applied no thinner than 4 cm, so that no air gaps remain.

- Plastering is recommended to be done at one time.

- The prepared surface is allowed to dry for a day, after which it can be worked with with Penetron. The consumption of Penetron waterproofing is 0.8 kg/m2.

How to care for surfaces treated with Penetron

It is important to ensure that the treated concrete is protected from mechanical damage for 3 days. Also, surfaces should not be allowed to dry out prematurely, as this will lead to peeling and cracking. To avoid this problem, you can use the following methods:

- spraying with water. A spray bottle or spray gun is suitable for this;

- cover the entire surface with plastic wrap.

Often concrete structures are lined finishing materials. This work can be carried out no earlier than 28 days after treatment with Penetron.

The Penetron brands are known all over the world. Due to their unique properties, they can be used both to protect new structures and to repair existing ones. Waterproofing Penetron does not allow water and other negative factors environment to destroy concrete structures, reliably protects them.

Scope of application

Treatment with such mixtures is necessary to protect prefabricated monolithic structures made of concrete and reinforced concrete. Can be used on surfaces coated with cement and sand based mortar.

Waterproofing with Penetron is also carried out on surfaces with defects and various design features. These can be cracks (no more than 0.4 mm opening width), porous base, seams, joints, abutments, communication inputs. In combination with other materials, the composition is used to stop pressure leaks.

Concrete structures are coated with the mixture twice by spraying or using a brush. Material consumption ranges from 0.8 to 1.1 kg/m2.

"Penetron" is used to protect the following objects:

- hydraulic structures (water tanks, swimming pools, wells, piers, etc.);

- objects of private and public construction, civil defense and emergency situations (balconies, basements, foundations, shelters, etc.);

- industrial and energy complex structures, transport infrastructure (mines, bunkers, storage facilities, pumping stations, tunnels, subways, etc.).

Composition and properties

Penetrating waterproofing "Penetron" is a dry mixture consisting of special cement, quartz sand from granules of certain fractions, and active chemical additives.

It is a material that has many excellent properties and features that make it easy and effective to use:

- the mixture is applied to a damp base, which does not require drying or preparation, this helps reduce financial costs;

- the composition is used according to the attached instructions;

- it is used to treat buildings both outside and inside, and can also be used at high hydrostatic pressure;

- when applying insulation from the inside, outside there is no need to protect against moisture;

- improves the grade of the concrete composition, increasing the percentage of its waterproofness, strength, and resistance to low temperatures;

- All beneficial properties persist even with high radiation activity and mechanical damage to the structure;

- concrete with “Penetron” can itself “heal” the pores and cracks that form on its surface by growing crystals, and with the subsequent ingress of moisture, this work resumes;

- Compared to other compositions, surface waterproofing with Penetron protects concrete for a very long period of time, this material is economical and effective: it is “alive” as long as the concrete is “alive”;

- the mixture is completely environmentally friendly, non-toxic, fireproof;

- can be stored for 18 months from the date of manufacture, but the sealing of the packaging must not be compromised.

The technical characteristics of the insulation are such that it will continue to work even after it dries. A concrete base treated with such a deep penetration composition is not afraid of mechanical wear and damage.

This is the latest generation material. When using it, the instructions and certain conditions must be strictly followed.

Additional materials

The additive "Penetron Admix" is used at the stage of construction of structures. It is added to the concrete prepared for pouring. With its help, you can reduce the construction time of an object: hardening of the concrete composition occurs simultaneously with the formation of its waterproofing. This method is widely used in the construction of underground parking lots, swimming pools, and tunnels.

"Penetron Admix" will maintain vapor permeability concrete structure, will make it resistant to corrosion processes. Cracks up to 0.4 mm in the structure are repaired. The foundation will not crack during the shrinkage process.

The Waterplug additive will help quickly remove pressure leaks in concrete, brick and stone structures. She catches on quickly. It has a high expansion capacity. It is environmentally friendly and can be used in drinking water tanks.

When waterproofing seams, cracks, joints and other defects, the Penecrit additive is also used. This is a high-strength material, it has a high level of adhesion to concrete, brick, stone and metal substrates.

Application technique

In a finished building, the basement most often needs protection from moisture. Coating "Penetronom" consists of several stages.

Preparation

The base is thoroughly cleaned with metal brushes to open the pores of the material. The old coating must be completely removed. If the basement walls were plastered, then you need to remove about 5 mm of the top layer.

The base is wiped clean from dust. Joints and cracks are cleaned and widened. After this, they need to be filled with the Penecrit mixture, diluted according to the instructions.

The concrete is watered generously. After this, you need to remove the resulting puddles. There is no need to dry the surfaces.

Applying the mixture

The attached instructions should be read carefully. Coating "Penetron" is prepared as follows:

- mix water and dry mixture in a 1:2 ratio, pour the liquid into Penetron (required!);

- using a drill operating at low speed, thoroughly mix the resulting solution; its consistency should resemble liquid sour cream.

The mixture is diluted in small batches, since the working time with it is no more than 30 minutes. If the material is applied manually, then a large amount of it simply will not have time to be processed. The composition must be stirred during operation. Water cannot be added again.

To waterproof structures with Penetron, use a synthetic brush, a brush made of synthetic fibers or a mortar pump with a sprayer. Experts do not recommend spreading the composition on the surface of the walls or rubbing it into them.

The first layer of the mixture is applied to a heavily moistened surface. It needs to set before a second coat is applied, this will take about 1-1.5 hours. The concrete surface must first be moistened.

The waterproofing solution must be applied evenly, without gaps, over the entire surface of the ceiling, walls, and floor. Material consumption will increase to 1.1 kg/m2 if there is concrete base strong drops, potholes.

After waterproofing the basement, its surfaces must be moistened over the next three days. Produce decorative finishing walls, ceiling and floor can be done no earlier than 28 days after installation of waterproofing.

Penetron brand materials for waterproofing concrete and reinforced concrete structures are world-class quality at a reasonable price.