Any cold smoked smokehouse should always be such that the meat is in contact with smoke heated to a temperature of +30...+50°C. As you know, smoke that has just risen above the fire or formed as a result of heating wood chips has a high temperature. Therefore, there is a need to cool it. This problem is solved by placing the firebox and smoking chamber at a distance, connecting them with an earthen channel or pipe.

Therefore, the design of most options has the following structure:

- Firebox.

- Channel-chimney.

- Smoking chamber.

As you can see, the smokehouse It is very simple and therefore any owner can make it at home.

Smokehouse-trench: option 1

It is better to implement a project to create such a smokehouse for cold smoking when the house or cottage is located near a river bank or near a steep slope. This is because, according to the drawings, the channel that will connect the firebox and the chamber with meat must have a bend whose angle is 90°.

The manufacture of this smokehouse includes next steps:

- Digging a horizontal channel in a clay slope. If the slope consists of other species, it is worth creating a different type of smokehouse for cold smoking. The length of the channel should be 1.2-2 m. For convenience, when breaking through the adit, you can tie a long pointed stick to the end of the shovel.

- At the beginning of the horizontal channel, expansions are made. It will be a firebox.

- Digging a vertical channel with your own hands. Its length should also be 1.2-2 m. In principle, the ratio of the lengths of the horizontal and vertical adits can be different. In general, the total length should range from 2.5 to 4 m. The end of the vertical hole should extend to the end of the horizontal one.

- Making your own cold smoking chamber. It can be done in different ways. The simplest one is to expand the top of the opening so that the diameter reaches 1 m. In this case, the height of such an expansion should be 0.5-0.6 m. The result will be that the meat will hang in the hole made in the ground. It is hung on rods. An alternative is a wooden or metal barrel, as well as a wide pipe lined with stone or turf. Best option- barrel.

- Laying the lid on the barrel. Moreover, they place it with their own hands so that there is a hole for the smoke to escape. If necessary, this hole can be enlarged/reduced. Instead of a lid, you can use burlap placed on the rods.

It is worth adding what else you need to know. Simply starting a fire and maintaining it until the end of cold smoking is not enough. Right first build a bright and short fire, then you need to reduce it, and also increase the formation of smoke. The last process is carried out by placing fresh leaves of hazel, strawberries, raspberries, and wild currants on the fire. If you need to get a tart taste, then you can use broom, willow, elm, ash and oak leaves.

It is worth adding what else you need to know. Simply starting a fire and maintaining it until the end of cold smoking is not enough. Right first build a bright and short fire, then you need to reduce it, and also increase the formation of smoke. The last process is carried out by placing fresh leaves of hazel, strawberries, raspberries, and wild currants on the fire. If you need to get a tart taste, then you can use broom, willow, elm, ash and oak leaves.

Medicinal herbs cannot be used for this purpose.

Smokehouse-trench: option 2

The project for its production also needs to be implemented on the clay bank. This smokehouse is stationary. They do it like this:

- Digging a ditch with your own hands. Length 3-4 m, depth 40-50 cm. According to the drawings, this ditch will be a chimney.

- The dug channel is covered with branches, on top of which turf is placed. The only place that is not covered is the end of the chimney. A hole is left here.

- Cover the left hole with turf or stones so that a structure resembling a pipe was formed. It should be wide and rise 1 m above the ground. Prepared meat or fish will be suspended in this structure.

- Rods and plastic film are used as a cover.(she is placed on the bars). In this case, you need to leave a hole that will allow you to control the draft.

Cold smoking in this design, depicted in many videos, is carried out in the same way as in the embodiment described above.

Duration of cold smoking - two days

Smokehouse-trench: option 3

This smokehouse option is excellent. The project for its implementation at home is carried out in such a way sequences:

- dig two holes with their own hands. The distance between them should be 1-1.5 m. The first of them will be the firebox. Therefore, it is made deeper than the other. Its depth is made 30 cm and width 40 cm. In this case, the far edge from the second pit is made flat. The depth of the second hole is 15-17 cm. As for the diameter, it depends on what will be used as a smoking chamber. It should always match the diameter of the barrel, pan or tank;

- a ditch is dug between two holes. It should be narrow (15-20 cm) and inclined towards the fire pit. The inclination of the channel will make the movement of smoke better. In this case, the chimney is brought out into a smaller hole so that its bottom is 7-9 cm above the bottom of the hole. This feature is often talked about in videos;

- since the dacha is not clay, but ordinary soil, which crumbles easily, the bottom and walls of the channel, as well as the pits, are compacted;

- take it with your own hands barrel or any other container and cut out the bottom;

- Place the barrel over the smaller hole. Three strong sticks are placed on its top. Meat will hang on them;

- cover the chimney with old covers, pieces of sheet metal or unnecessary iron. Soil is poured on top;

- similar actions are performed over the combustion pit. However, they cover 2/3 of its area with their own hands.

The uses of this smoker for cold smoking are as follows:

- Putting firewood into the firebox.

- Making a fire.

- Laying rotten logs on the coals.

- Filling the pit under the smoking chamber with hay soaked in the evening. It is laid loosely, but not loosely.

- Hanging meat.

- Sawdust is poured onto the logs.

Some people use fresh grass or dry hay instead of wet hay. This is not entirely good as the meat may become more bitter. Dry hay can catch fire, which is, of course, undesirable. The role of wet hay is to filter and cool the smoke. In addition, it adds flavor.

Barrel and pipe construction

Which is often shown in videos, provides the following components:

- Chamber for burning wood.

- Two pipes welded to this chamber. Both are chimneys. Through one, smoke enters the smokehouse (it cools while passing through it), and through the other, excess smoke exits. The first pipe is 2-3 m long.

- Chamber for cold smoking.

This smokehouse, like all other devices for cold smoking, has considerable dimensions and occupies a considerable area. If you create it at home, then it’s worth making the smoking chamber big. In this case, the use of the smokehouse will increase, since you can hang a lot of meat in it.

Implementation shown on different lines  The scheme is implemented as follows:

The scheme is implemented as follows:

- Making a firebox.

- Barrel preparation or constructing a smoking chamber from other materials.

- Installation of two chimneys.

If available, then the work on manufacturing the firebox is reduced to a minimum. In this case, you need to make an additional hole for the chimney with your own hands. It should be installed below the hole to which the pipe supplying smoke to the smoking chamber will be connected.

If there is no stove, then you can weld a firebox from sheet metal or use gas cylinder

. The dimensions of a sheet metal firebox can be 40x40x30 cm. According to various videos, the firebox is made in such sequences.

- Cutting rectangles from a sheet of metal with a thickness of 2-4 mm. The dimensions of the rectangles are determined based on the above firebox parameters.

- Two holes are cut in the front wall. They must be on top of each other. The top one should be big. Firewood will be placed through it. The bottom should be on the bottom side. It will be a blower.

- The cut out rectangles are welded. To make the geometry final metal box was correct, first connect the two parts by drip welding. The connection will not be strong, but it will be sufficient to prevent the sheets from falling apart. Next, adjust the two connected sides so that they form a right angle. For this, a carpenter's corner is used. Afterwards, full welding is performed. Features of its implementation can be seen in various videos.

- At the top of a welded metal box cut a hole with a diameter of 10 cm. This hole should be located near the back wall. A similar hole is cut in the back wall. It is made in the middle of the height of the wall, shifted slightly to the side.

- Door hinges and a hook are welded onto the front wall for fixing the door handle.

- The blower is made from two corners and a strip of metal with a thickness of 0.5-1 mm. The corners should be longer than the width of the opening. Their dimensions are 15x15 mm. One of their sides is cut so that 2-5 mm remains. The cut side is applied with your own hands to the front wall and welded. The corners must be in a horizontal position. One below the hole, the other above. Next, it remains to cut a strip of metal with a width that is equal to the distance between the cut sides of the corner. The length of the strip should be 2-3 cm longer than the length of the corners. These 2-3 cm are bent at a right angle. Afterwards, a strip of metal is inserted between the corners and the size of the blower hole is adjusted with it.

- Making a support for the firebox. For this you can use profile pipe or just a brick.

After making the firebox at home, they begin to prepare the barrel. This process comes down to cleaning the barrel of oil, paint or whatever substance was in it, and cutting a hole with a diameter of 10 cm in the side. It can be larger. In this case, the chimney will be able to completely enter the cold smoking chamber.

Also do it yourself supports the rods on which the meat will hang. To do this, you can drill holes and insert rods into them. An alternative is to use wooden rods and wire. One piece of wire is wrapped once around the end of the rod. The wire should fit into the pre-cut groove. Next, the wire is twisted and a hook is made from its ends, which will be hung on the upper edge of the barrel. Similar actions are performed at all ends of the rod.

If there is no cover, it is cut out of sheet metal. In order not to move it dozens of times, it is worth making a vent in it, like in a firebox. True, in this case this design will be used to regulate the smoke output.

The barrel must be positioned so that its bottom is 20-25 cm above the top of the firebox. In this case, the distance between the two parts should be 2-3.

Next they are welded to the firebox chimney 2-3 meter pipe. A pipe elbow will be placed near the firebox. The other end of the chimney is welded to the barrel or inserted into it. The chimney should be placed at an angle. A 1-1.5 m pipe is welded to the lower opening of the firebox. It must be vertical.

Next they are welded to the firebox chimney 2-3 meter pipe. A pipe elbow will be placed near the firebox. The other end of the chimney is welded to the barrel or inserted into it. The chimney should be placed at an angle. A 1-1.5 m pipe is welded to the lower opening of the firebox. It must be vertical.

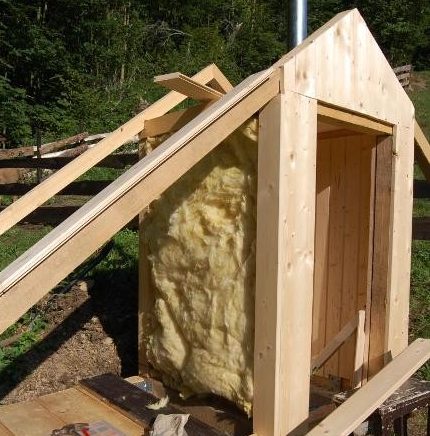

You can also use boards to make a smoking chamber. They are used to make a structure that resembles a small house.

Brick construction

Its diagram is almost the same as the drawing of the above-described option. However, there is no vertical chimney; the firebox, smoking chamber and transition between them are made of brick.

Includes next steps:

- Pouring concrete screed. Under the firebox and channel, the thickness of the screed is 12-15 cm. Under the smoking chamber it is worth pouring a deeper foundation. It is better to make it 50 cm.

- Waterproofing. Lay 2-3 layers of roofing material.

- Firebox masonry. It must have an ash pan and a furnace. The smoke channel extending from the furnace is made on the side of the firebox.

- Chimney laying. It is made of brick. In this case, a pipe with a diameter of 10-30 cm is walled up. The pipe can be used metal, asbestos-cement or ceramic. A special stand is made under the pipe. It should be such that the pipe is in a flat position. The upper end of the chimney should enter the smoking chamber.

- TO adjustment of the smoking chamber. It is made so that most of it is above the firebox level. The bottom level should coincide with the lower edge of the chimney pipe. Often the bottom is 50-60 cm above the ground. Below it you can make a chamber for firewood. The smoking chamber can also be made of wood. In this case, under it you need to build a brick structure with a niche for firewood. The height of this structure is made the same as the height of the chimney masonry. (1 votes, rating: 4,00 out of 5)

This method is also suitable when you want to diversify festive table, pleasantly surprising guests and pampering your household. Home smokehouse, which is suitable in all respects specifically for the existing barbecue, can be made from an ordinary pipe.

The first version of a smokehouse made from a piece of pipe

Horizontal version for barbecue

Collecting tools:

- Bulgarian;

- welding machine;

- chalk (for marking);

- ruler.

Required parts:

The length of the product is limited by the width of the grill; the smokehouse should not protrude more than 5 cm on both sides.

- 2 sheets of metal (with sides no less than the diameter of the cylinder);

- metal corners;

- loop;

- pen.

You will also need a grate and a tray for collecting fat. You can also make a pallet yourself from stainless steel sheets.

Assembly

On inside We weld the corners of the pipes longitudinally so that they are slightly above the diameter line. They should be 3-4 cm shorter than the total length on both sides. These are guides for the grille and tray. The next step is to weld one side with a circle cut from a sheet of metal. The other side will serve as a door. There you need to weld a hinge, and to it a second “round piece,” a handle and a hook for closing the door.

Finding a suitable pipe on the farm is not difficult. You can weld either a “U”-shaped profile or pieces of a corner. We weld one end tightly. You can make the grate yourself from the mesh, welding it to the frame. Attach a lid.

On the grill itself, weld 2 pieces of corners; they will keep the device from turning over. Thus, the unit assembled with your own hands is ready.

Important. The door should not fit completely, allowing very little air movement.

Portable smokehouse

A portable smokehouse for avid fishermen who love to eat delicious food is also quite easy to assemble. It can be done in two ways. There is a slight difference in materials and technique, the tools are still the same.

Option 1

- pipe (diameter not less than 377 mm);

- 2 loops;

- metal corners;

- 2 handles;

- 2 cap locks;

- 2 sheets of metal (with sides no less than the diameter of the smokehouse cylinder).

Assembly

The length of a handmade product is limited only by imagination. Both holes are welded. Cutting out the door. To do this, let's place the resulting cylinder horizontally. We draw a longitudinal line that does not reach the ends by 10-15 cm. We draw a second line parallel to it, at a distance of 1/3 from the perimeter of the product. We connect them with transverse lines and cut out the resulting rectangle with a grinder. We connect the cut piece to the body with loops. Inside, we weld the corners longitudinally, do not forget to leave gaps between the pallet and the end walls for smoke circulation. We fasten the locks and other small items. Voila, the smokehouse is ready.

Such a structure can be placed on flat stones, bricks or arched supports to start a fire under it.

Guide corners not only secure welding machine, they can also be mounted on rivets.

Option 2

From the previous version, we exclude locks and hinges and add a metal tape (at least 5 cm wide). Everything else is the same.

Assembly

As in the previous version, the length depends only on your wishes. The first step is to fasten the corners inside as described in option No. 1. WITH outside Approximately in the middle, place the handle. Then we brew one side “round”. A metal strip is welded around the perimeter of the second “round piece” so that it fits tightly onto the pipe. This will be the door, naturally, a handle is also attached to it in the middle. Pour sawdust or wood chips onto the bottom, put the fish in, and close it. All that remains is to light the fire and wait for the smoking process to finish. In such a home-made unit, food is prepared from 40 minutes to an hour and a half.

Cylindrical smokehouse oven

Vertical smokehouse

There are people who prefer vertical structures, but even in this case, the smokehouse is quickly and easily assembled with your own hands. The difference between vertical structures is that several grates can be placed there and only 1 tray is required to collect grease. In this case, the entire focal point is in diameter; the larger it is, the wider the smoking grates will be; accordingly, more products (fish, poultry, meat) can be placed at a time. A vertical smokehouse is assembled using the same tools as a horizontal one.

Materials

- pipe (diameter not less than 426 mm);

- pen;

- metal tape (at least 5 cm wide);

- fittings;

- metal corners;

- pipe 10 cm (small, for the chimney);

- 2 sheets of metal (with sides no less than the diameter of the workpiece).

Assembly

We weld one side of the pipe with a “round”, the metal must be thick, otherwise it will quickly burn out - this will be the bottom. We weld a ribbon onto the second “round piece” so that it fits tightly - this will be the lid. We make a hole in the lid for the chimney, don’t forget about the handle. We bend the reinforcement with the letter P, so that this “letter” fits into the pipe. There should be two such “letters” and they must be welded one to the other, having previously crossed each other. In the places where the gratings are attached to the fittings, we weld the corners for stability. We place this entire structure in the smokehouse.

The distance between the grates in height should not be less than 20 cm, otherwise the products will be poorly smoked.

We weld corners to the bottom - these will be the legs. True, instead of metal corners you can use bricks, depending on who you like. You can also use thick burlap instead of a lid, after wetting it. As it turned out, assembling a smokehouse with your own hands is not so difficult.

Good evening! I made a cold smokehouse, and instead of draft - inflow!!! The design is as follows: A pit 0.7 * 0.7 with a depth of 0.6 m is lined with bricks, the exit is under a chimney, the length of which is 8 meters underground in 100 mm asbestos-cement pipes, a slope of 0.7 m by 8 meters, at the end there is an assembled sealed wooden cabinet from a floorboard with a lock 0.5 * 1 m and a height of 1.7 m. An influx was found in the fire from this smokehouse into the firebox at a temperature of -3 C! What's wrong???

Stanislav, Moscow region.

Hello, Stanislav from Moscow province!

I am not such a great specialist in the stove business to give a comprehensive answer to the cry of your soul about cold smokehouse in a similar original design.

But, again, in my subjective opinion, all the canons of stove art are violated in your construction.

I once described something similar about cold smoking of fish in a device on the steep bank of the Oka River. And everything was fine there, but the design was significantly different from yours.

Let's try to break down the structure of your smokehouse.

A pit lined with bricks, an exit under the chimney, a long and narrow asbestos-cement pipe in the ground, a slight slope, a sealed smoking box. And to boot, sub-zero temperatures. And instead of draft there is a return flow (turning the flow of flue gases back).

That’s right, or rather, the way you would do it, then for a cold smoked smokehouse you need a similar fireplace, lined with brick, but it’s better not in the ground, but above its surface. First, it is mounted under the hearth, that is, a flat platform with a slight slope towards the front side. There should be a small channel in the hearth, which is covered with a grate. Underneath there was a blower or ash pit (channel) for collecting ash and ashes. The vent must be covered with a door.

The outlet under the chimney should be approximately 1/4 -1/3 of the hearth area. Pipe with a diameter of at least 150 millimeters. The slope in which it is laid, the more slope it has, the better. The pipe is not simply laid in the ground, but is isolated from it using either a larger diameter pipe or a box, for example, made from edged boards. The space between the pipes is filled with dry soil. Otherwise, condensation often forms, the pipe is cold, and the draft is reduced.

At the beginning of the pipe, near the chimney outlet, there should be an adjustable valve. The pipe length of 8 meters is too big. Even half is enough for the eyes.

The smoking cabinet has two openings - one at the bottom, where the chimney from the fire enters, and the second at the top. Above the second hole there is a pipe with an umbrella visor.

All these subtleties and wisdom exist to create normal draft and remove flue gases.

That is, dry fuel is taken in a small amount, a fire is built, the ash pan door is opened slightly, as well as the pipe valve. After kindling it is laid required quantity firewood The brickwork and the pipe in the ground are warming up.

The draft is adjusted by opening the ash pan (blower) door more or less and the pipe valve.

The chimney umbrella serves not only to cover it from precipitation, but also to protect it from the wind, which in some cases can be directed from top to bottom, causing smoke to rush back.

An asbestos-cement pipe cannot be used in a smokehouse, since asbestos is a carcinogen that causes cancer, and in addition it is also used for cooking.

Ukrainian cold smokehouse

A friend of mine in Ukraine has a whole neighborhood dedicated to preparing cold and hot smoked products. The design of his smokehouse is as follows.

On the surface of the ground there is a firebox made of red unplastered brick. She represents herself concrete screed size 0.5/0.5 meters. Two brick walls, also 0.5 meters high, are laid opposite each other on it. Everything is half a brick thick. There is a metal grating on the first row of brickwork. On which they place an armful of firewood. They burn normally.

The walls are covered metal sheet 5 mm thick. (You can install a frying pan, a saucepan, and a cooking pot on it).

In the upper part of one of the walls there is a hole into which a rectangular pipe-box with a cross-section of 100/200 millimeters and a length of about 2 meters is inserted. An auger box from a combine harvester was used as it, although it can also be made from a sheet of thin iron. The other end of the pipe enters the smokehouse.

The smokehouse is a well made of brick with walls half a brick thick, without plaster. Size 0.8/0.8 meters and height 1 meter. It stands 10 centimeters higher than the firebox. The end of a two-meter pipe enters the smokehouse at a height of 15 centimeters from the surface of the earth.

IN brickwork at several levels there are holes for pins made of reinforcement (it is also possible to use skewers). Hooks are placed on the pins, from which the products to be smoked are hung.

A sheet of metal is laid on the surface of the earth. It serves as a tray onto which fat from smoked meats drips. It should be washed and cleaned after each preparation of food. Otherwise it will get so bad that mom don’t worry.

The smokehouse is covered with several edged boards so that there are gaps between them. The cloth from the bag is placed over the boards. A closed volume is created that provides both smoking and the passage of smoke through the burlap. With normal traction.

For different smoking modes, in addition to the firebox with a metal pipe, they also make a second firebox located on the directly opposite side. It is exactly the same as the first one, but with a different pipe, which is made of brick. If a metal pipe heats up quickly and has a high temperature, then a brick pipe heats up more slowly, but retains heat and warmth longer. And to feel the difference in cooked smoked meats, you need to cook it this way and that way.

A mandatory accessory for production is a “pshikalka”, which is a one and a half liter plastic bottle in a cork in which a dozen holes are pierced with an awl. Fill the bottle with water and, if necessary, knock down the firebox flame that is too large.

Wood from fruit trees (cherry, plum, apple) is used as firewood. WITH coniferous species, and even more so with alder in Ukraine it’s stressful.

For example, to prepare cold smoked chicken, use brine (salt solution at the rate of a pack of salt per 10 liters of water). They put onions, cherry leaves, currants there, add allspice, bay leaves, and sweet bell peppers. Place plucked and washed gutted chickens for 10 hours.

After which it is removed and placed in a smokehouse, which is already heated. After 4 - 6 hours, the chickens are ready to eat.

Of course, in addition to chickens, you can smoke meat, lard, and fish. And depending on maintaining a higher or lower temperature regime and holding time, both hot and cold smoking can be achieved.

But all this is achieved experimentally. You just need to write down all the characteristics each time (of the product, the size of its pieces or carcasses, cooking time, approximate temperature, firewood used, etc., etc.)

Ask a question to Semenych (author of materials)

Our website is regularly updated with interesting and unique materials and articles on the topics of ovens, barbecues, grills and barbecues. If you would like to receive information about this, subscribe to our website's newsletter. We guarantee that your address will not be shared with third parties.