Relatively recently, inverter welding machines appeared on the shelves. In addition to their compact size, a significant difference between household inverters is the light weight of the installation, which allows you to carry such a station in your hands. But the property that especially attracts the consumer is the ability to work from regular socket at 220V.

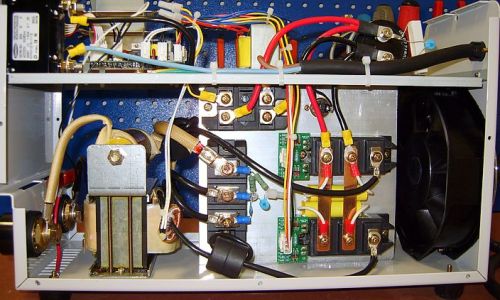

The output has solid-state regulators that modulate the switching speed of the switching transistor. What are the advantages of this new inverter driven design? First, the main power transformer operating at 000 Hz is significantly more efficient than 60 Hz transformers, which means it can be smaller. This photo shows a tungsten gas inverter welding arc.

Therefore, machines designed with inverter technology have a huge advantage in terms of weight, making them easy to transport. At the moment, we have only talked about inverter welding machines that supply direct current. For several years this is all that can be found. Then someone had the idea to include two inverter welders in one box.

Models of inverter devices are constantly being improved, and additional functions are added. In this regard, a buyer who decides how to choose a welding inverter for his home may face an almost impossible task. What to look for when selecting suitable equipment among several dozen different models?

More high frequencies may be useful for thin welding materials. As frequency increases, the arc and welder become narrower and cause deeper penetration. During the portion of the cycle when the electrode is positive, weld penetration is reduced and more heat is transferred to the tungsten electrode. However, during the positive electrode portion of the cycle, the arc acts to remove oxides from the aluminum surface, making welding easier. We didn't need that many positive electrodes to clean properly.

The most modern power supplies have allowed us to change the proportion of negative and positive electrodes. About 65% negative electrodes and 35% positive electrodes were found to provide adequate arc cleaning and good penetration.

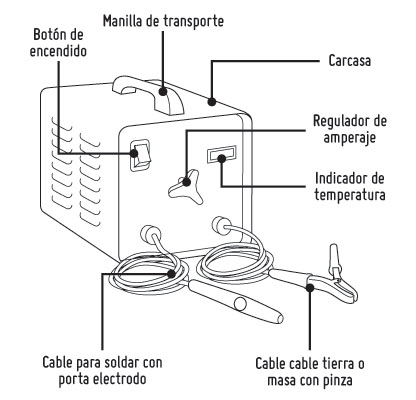

Operating principle of a household welding inverter

The best household welding inverters for home easily cope with the main task of converting voltage to ensure a stable arc. In fact, each of the devices, with varying efficiency, performs four important stages of transformation electric current. Namely:- Converting AC to DC.

- Transformation constant voltage back to AC, but with a high operating frequency.

- Reducing the frequency to the required parameters.

- Reverse rectification of already reduced high frequency voltage.

At first glance, it may seem that such constant transformations are unjustified, but as a result of their implementation, the productivity of the equipment significantly increases, and, equally important, the weight and dimensions are reduced.

However, most of the energy from the arc was still heated by the tungsten electrode, so large diameter tungsten electrodes were needed. Inverter power supplies provide sufficient arc cleaning with only 15% positive electrodes. Reducing the number of positive electrodes makes the process more efficient, increases weld penetration and reduces the amount of heat applied to the tungsten electrode, meaning smaller diameter electrodes can be used.

This concentrates and narrows the weld more. Finally, new inverter power supplies are programmed using software. This allows you to easily change the characteristics of power supplies. The power supply that can be seen in the photo was first designed as an inverter, welding machine For gas metal. It contains a large number of different programs for regular and non-traditional control algorithms for gas welding machines. A range of programs for gas arc welders where pulsation parameters have been optimized for specific fillers and cable sizes.

For your home, it is better to choose an inverter welding machine that operates on a voltage of 220V. A household installation will allow you to perform minor household work, and to connect it, you will only need to insert the plug of the device into one of the sockets.

How to choose an inverter semi-automatic welding machine for your home

There are six main criteria that you should pay attention to when choosing a reliable welding inverter for your home or garden. The quality of the installation will largely depend on how much the buyer is willing to spend. Even among economy class models, you can choose an acceptable option if you pay attention to the following:- For what purposes do you plan to purchase a household inverter welding machine? The thickness of the workpieces and pipes largely influences the selection of the electrode, the combustion of which, in turn, requires a certain power of the installation.

- Electrode diameter - this coefficient affects the ability to carry out work using the device. The diameter of the electrode is selected depending on the type of weld and the thickness of the metal being processed.

- Operating current - choosing a welding inverter for a summer house is much easier if you consider that a power of 30-40A is required per unit of electrode. Therefore, for a “C” electrode, an output current power of 90-120A will be required.

- The type of network being connected - the fact that the inverter will be used for a summer residence does not mean that it is necessary to limit the choice exclusively to equipment operating on a standard voltage of 220V. Some models are designed to operate on 380V, and they have a unit installed that adapts when connected to a generator. Household inverter-type welding machines for dachas, operating on 220V, may also have a similar device.

- Duration of continuous switching on or PV. This ratio is displayed as a percentage. The most common are devices with a duty cycle of 60-80%. In practice, this means that the equipment can operate for 6-8 minutes respectively. After this, the welding inverter will automatically turn on the idle mode.

- Rated current is an indicator that determines the load at which the device will not overheat. Some manufacturers indicate the maximum current instead of the rated current. Which is not entirely correct and does not allow us to make correct calculations.

However, due to software programming, it is also possible to use it as a power source for shielded arc welding or tungsten gas arc welding. It can also be reprogrammed in the field very quickly. In addition to all this, the power supply weighs about 36 kg and can send about 425 amps.

A full wave rectifier converts alternating current from 50 Hz to 60 Hz into direct current. High speed switches improve welding. Going beyond 20 kHz improves efficiency, reduces weight, and exceeds the maximum frequency humans can hear. Digital controls determine the rate of change of the transistors.

How can these criteria in practice affect the choice of a household inverter welding machine for the home? For example, it is planned to process metal 3-4 mm thick with a “C” electrode, then it is easy to calculate that the operating power should be 120 A. But if the installation’s PV is 40-60%, then these calculations will be erroneous.

The current is "softened" by a filter circuit suitable for welding. The inverter welding machine is relatively new and innovative, it is a type of welder that has more advantages over the conventional welding machine. Inverter welding machines are complex compared to traditional aluminum welding transformers.

It cannot be denied that the first inverter welding machines were first introduced, inverter welding machines have created many ways to solve problems, using new technologies, however, inverter technology has become the most reliable, economical It has its own advantages.

The fact is that in addition to calculations related to power, it is also necessary to take into account the margin for equipment overheating. In case of low duty cycle, about 30-50% of power should be added. For such work at home or in the country, you will need household inverter welding machines rated at 160-180A.

Which company to choose a household welding inverter

As already noted, inverter-type household semi-automatic welding machines may differ in quality, reliability and cost. The choice of manufacturer of these products significantly influences these criteria. We can conditionally divide all types of equipment according to this criterion into three main categories:- European concerns - they produce productive inverter welding, with additional systems helping to avoid typical difficulties during work: sticking of the electrode, overheating of the device, etc. Household devices from European manufacturers such as EWM, Telwin, etc. can cope with high loads and can be classified as semi-industrial installations. The pricing policy of the companies is such that on average you will have to pay for an inverter welding unit as for an industrial Chinese machine. But the high cost guarantees quality and long service life.

- Domestic manufacturer - optimal solution For your home, you will want to purchase an inverter semi-automatic welding machine made in Russia or Ukraine, especially if you plan to use the installation exclusively for domestic purposes. The quality is different from Svarog, Patona and others. It should be borne in mind that sometimes Chinese manufacturers disguise themselves as well-known Russian brands. Therefore, when purchasing all kinds of Tempos, Rhythms, etc., most likely, you are buying a Chinese fake, which begins to emit the smell of burning plastic at the slightest overheating.

- China - inverter-type semi-automatic home welding machine from Chinese manufacturer It's a risky business. The only thing that can be tempting about Chinese products is the low installation cost. If you plan to use the welding machine occasionally, you can choose something from the official factory in China. Reviews show that the Resanta model has good characteristics.

The main advantage is its size, small, compact and somehow the weight is light and portable. The inverter welding machine can be connected to 110V in any local current, at the same time the high voltage current eliminates the need to use an industrial generator, when consuming energy, it can save overall energy consumption. Additionally, it may be better accepted in jobs that require immediate speed.

The fairest thing is to pay for additional features tolerance and usual household use and leave problems from the device, buy a reverse welder, reverse welders do not provide possible solutions problems with soldering, but this is honestly a milestone in the advancement of inverter technology.

It is best to buy the model you like in stores that are official representatives of the manufacturers. This way you can avoid counterfeiting and purchase a truly high-quality inverter-type household welding machine.

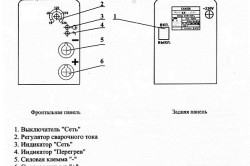

Connecting the welding inverter to a household network

The inverter device is connected using a ready-made extension cord and an electrical plug. The difficulty is that some external power supply networks, especially in older houses, are not designed for such a load. But if the house was built according to modern GOSTs, then there should be no problems with the connection.Electrical networks designed for a power of 16A can satisfy the current needs of a household welding device. In addition, the operating principle of inverter household models reduces the number of overloads by electrical network Houses.

Inverter welding machines

Portable inverter welding machines are very productive, have greater availability, and the welding machines are connected to generators. Therefore, portable welding machines can perform multiple operations in less time than conventional welding machines.

"Svarog": reviews and characteristics

Additionally, other factors such as tension, material thickness, and welder cycle time must be considered before charging. Portable welders weigh significantly less and appear more compact in time, while maintaining the characteristics of a conventional welder. The portable welding machine comes with many additional features and consumes according to your needs. An arc welder is a tool that allows you to join two pieces of metal using heat.

If the wiring is not designed for increased electricity consumption, then you can connect directly from the meter by connecting to the power cable terminals.

If connection welding inverter it is impossible to connect to the home network; the installation can be powered directly from the power line. To do this, you will need to obtain permission from your local energy sales office.

Arc Welder Parts

The process varies depending on the energy source used, the type of electrodes and the use or absence of gas or other material that changes the interaction of the components with the atmosphere.

The electric current forms an electric arc between the weld metal and the electrode being used, forming an alloy at the welded joint. Electrodes are usually made of mild steel and coated with flux, which prevents oxidation and promotes welding.

Selecting inverter welding for household needs should be based on the final cost of installation, the required performance of the device, the type of network being connected and the power source. All these criteria will help you choose the most suitable equipment for your garden.

- General recommendations for selection

- Domestic production

- Types of welding inverters

For welding enthusiasts, there is always the question of purchasing the appropriate tools. But how to choose a welding inverter correctly and not make a mistake? To do this, there are several points that must be taken into account in order to choose the right equipment.

You can see more information in the video

What tools are used for welding? AC: Electricity that flows at intervals or in cycles is electricity that reaches households and businesses. Input material is the electrode, and the power regulation will be based on the thickness of the electrode.

The required material is also an electrode, and its characteristics are electronic current regulation, ease of use, its light weight and the ability to connect to generators. An ampere is a unit of electrical current, the power of the current is measured in amperes.

The inverter welding machine is equipped with double insulation, so it is absolutely safe for electric welding work.

Since the welding inverter operates from the mains, you should remember that the voltage in it is not constant. Today, most models have protection against such surges. The most optimal level for such equipment is 20-25%. Such a system will protect against failure if the differences are in the range from 170 V to 270 V. But here it is worth mentioning right away that such a high indicator is more suitable for industrial use than for household use. In household use, an indicator of 10-15% is enough. After all, the stronger the protection, the more expensive the inverter will cost.

Ampere ranges from 300: for large structures, mechanisms, tanks, pipes of large thickness. This gas acts as a shield against oxygen in the atmosphere, preventing oxidation and other types of metal contamination. The steel core of the electrode, when melted, joins the pieces and fills the spaces.

In this process the electrode is tungsten and is not consumed, and inert or semi-measurable gases are used as shields. It is a slow and precise process that requires a lot of technology, but allows you to collect small metals and do delicate work. It has a generator that provides less current. This type of welding is widely used in bicycle manufacturing.

The next point that you should pay attention to when choosing is ventilation. During operation, such a device heats up and therefore requires cooling. And here dust gets in through the ventilated holes. Each manufacturer has its own methods of protection.

This is a similar method to the previous one, but uses a non-consumable electrode and an inert gas, which is supplied separately, and serves as a shield. Its features make it easy to maneuver. It is a machine that can carry out various types of welding and support the use various types electrodes.

This is a gasoline or diesel powered tool that basically allows you to work in remote locations. Its most repetitive welding type is the manual arc, capable of welding all types of electrodes up to 4.0 mm in diameter. Electrodes are metal rods that are used as a circuit pole in arc welding as an electric arc is created at the end of the circuit. They differ in the work they do, resistance strength and thickness, in addition to the type of cord and termination.

The most common is tunnel ventilation. With this system, the radiator is located along the length of the entire body, but the main components are located inside. This build really helps if work is carried out in very dusty and polluted places.

But again, if you choose a welding inverter for home use, then such serious protection is simply useless. Therefore, alternate cleaning is enough. To do this, remove the body of the device and remove the accumulated dust with a soft brush or blower.

According to the amperage, the tool represents the diameter of the electrodes you will need for your job. The size of the electrode is related to the power of the welding machine, that is, at higher power, a larger diameter electrode can be used.

This point must be taken into account, as it is important for the operation of the machine.

- It is suitable for all iron applications and repairs.

- This electrode features a blue dot, especially for thin sections and plates.

- And green dots, especially for lightweight structures such as window frames.

Printed circuit boards are considered a very important component of a welding inverter. In fact, their breakdown is quite common, and the cost of repairing them is expensive. Therefore, custom boards indicate that such a model breaks down extremely rarely, so there is no need to keep spare parts for free sale.

The range of operating temperatures in the inverter is also important. If the environment in which welding will be carried out (for example, a factory) has high performance, then such equipment will automatically turn on protection. The maximum permissible temperature is +40°C, but if it is higher, then it is advisable to stop work, otherwise the inverter will simply fail.

Recommendations for use and maintenance

Think that it should be lightweight, practical, and completely insulated. The use of welders can affect the voltage that powers other types of electrical devices. Electrode holder cables can be affected by cuts, mainly due to the weight of the electrode holder. It is recommended that whenever the welding machine is used or stored, the electrode holder should be placed on the machine and not hanging to avoid such damage. Before using it, check the condition of all welding elements to ensure the job is completed correctly and safely. Do not modify the welding machine cable provided by the manufacturer unless you have necessary knowledge or the need to modify the machine. The welding machine must always be in correct position and indicated by the manufacturer at the time of use. If you need to weld in a specific place, you must stop the welder and move him to the place where you are going to work so that the machine does not tip over or work incorrectly. If you need to improve the end of the welding cord, use an angled grinder with cutting discs. You can also use a metal file which, with longer working hours, will allow you to finish the fine. The soldering process requires the use of appropriate clothing with items such as safety shoes, leather gloves, a leather apron and, ideally, denim trousers and jackets.

- Therefore, it is not recommended to use it simultaneously with other tools.

- For welding you must use.

As for low temperatures, it largely depends on the internal configuration. The fact is that microcontrollers, capacitors, transistors and other similar elements are very sensitive to frost. Moreover, each detail has its own individual limit. Therefore, depending on this indicator, the operating temperature range can vary significantly for each individual model.

Most often, the manufacturer refers to GOST, then in this case for foreign brands it is EN 60974-1, and for domestic brands it is GOST R IEC 60974-1-2004. This mark indicates the possibility of using the inverter both at +40°C and at -40°C. But it’s worth mentioning right away that such markings do not guarantee that the equipment will start freely at temperatures below -15°C. And all because electronics do not like low temperatures, and when they start up, the overload signal most often comes on.

If you nevertheless load the equipment with work in the cold, then due to heating, condensation forms, which settles on the insides of the inverter, which is quite destructive for them. Therefore, if the instructions do not clearly indicate that the selected model is intended for work at low temperatures, then it is better to refrain from using it.

Return to contents

How to choose the right welding inverter?

Judging objectively, choosing an inverter is quite difficult; many points need to be taken into account.

You need to know that inverters have a classification: household, professional and industrial. They were named so according to their scope of application.

For example, household inverters have low power, so they can work for approximately 15-30 minutes, after which they need to cool down (about an hour). Professional models come with a more powerful filling, so their operating time is 8 hours, that is, one shift. Well, industrial devices can be used 24 hours, taking into account short breaks.

In fact, household and professional tools are similar in their technological characteristics. Therefore, before choosing a welding inverter, it is necessary to determine its scope of application.

Return to contents

Manufacturers of welding inverters

First of all, you should pay attention to such nuances as:

- are there service points in the city;

- availability of a product catalog;

- is the manufacturer's resource full?

- What languages are the included instructions in, and if they are translated, what is the quality of the translation?

As for foreign representatives, the most popular brands are Wester, Fubag, Profhelper, Gysmi, Blueweld, Neon. Therefore, a few words should be said about each.

The Wester welding inverter has fairly high output power. This suggests that when working with this technique, it is possible to use electrodes up to 0.5 cm. Moreover, their equipment does not depend on the parameters of the incoming voltage, be it 200 V or 180 V.

Their models are equipped with a protection system against short circuits and electrode sticking. This makes operation much easier, and the quality of work always remains high.

Fubag makes its inverters quite universal, which makes it possible to work with various types welding In these models, the timing of arc ignition is significantly simplified, which significantly affects productivity. There is no need to change electrodes and clean the seams from boiled slag.

The Resanta inverter welding machine has small dimensions and is successfully used in hard-to-reach places.

A representative of such an inverter combines manual arc welding(MMA) and semi-automatic (MIG/MAG). Such analogues have smooth adjustment of voltage and welding current supply.

Profhelper has several lines - Prestige, Solution, DaVinci, Euro Tig, Plasma Cut. The manufacturer equips its models with forced cooling systems. They can work in an environment shielding gas, using Mig-Mag technology or flux-cored wire. Such inverters are very popular because they have the option of stepwise current switching, smooth adjustment of current supply speeds and overheating protection.

Gysmi is a French company that produces welding inverters of mobile dimensions. At the same time, they are quite easy to use and quite reasonable in price. These models have multifunctional characteristics.

Blueweld produces inverters designed for working with thin metals. Excellent performance of lingering seams.

Neon is in great demand now. Her technique is designed for manual welding. The power supply for such a welding inverter comes from the electrical network, and they are quite mobile, so there are no problems with transportation, especially if there is a need to work on the outside of the building. These units do not consume a lot of energy and make it possible to weld even in hard-to-reach places.

Return to contents

Domestic production

The Russian-made domestic welding inverter Spets IMMA-200 has been tested satisfactorily and meets all the necessary parameters.

But it is worth noting domestic manufacturers, because they are also quite often found on the market. Especially some representatives.

"Resanta" is a representative of S.I.A. Such inverters are produced in accordance not only with domestic standards, but also with international ones. They are distinguished by high technology and productivity.

“Master” models easily cope with hard-to-reach places. Such welding inverters are included in the category of professional equipment, since thanks to them it is possible to carry out work of increased complexity.

Forsazh equips its equipment with fairly high-quality components. Such devices are not large in size, due to which they are quite mobile. They have thermostats and forced air cooling, so they are not afraid of overheating.

Welding occurs using DC using rutile, cast iron, base or stainless steel electrodes.

This inverter has fairly easy arc ignition, built-in thermal protection, and most of its accessories are removable.

“Svarog” has an excellent price-quality ratio. Such models are small in size and do not require special skills in their operation. They can have housings made of both metal and plastic. The standard package includes welding cables, and as an addition there may be a case designed for transportation.

“Bars” is also very popular, since high-quality equipment is bought for relatively little money.